Cutting Mechanics & Engineering Analysis

Drill bit head geometry directly impacts cutting efficiency, hole quality and tool longevity. 2‑cutter designs achieve higher unit pressure through larger cutting angles and reduced contact area for rapid penetration; 4‑cutter designs distribute impact forces across more cutting edges for stable trajectory control and superior hole roundness; cross‑head designs use intersecting cutting paths to maximize guidance and jam resistance.

2‑Cutter System Technical Features

- Cutting Angle: 130°‑140° aggressive angle, concentrated cutting force

- Flute Design: Deep flutes for smooth chip evacuation

- Contact Area: Minimal contact reduces friction heating

- Cutting Speed: Fastest in soft to medium materials

- Optimal RPM: 800‑1200 RPM efficiency zone

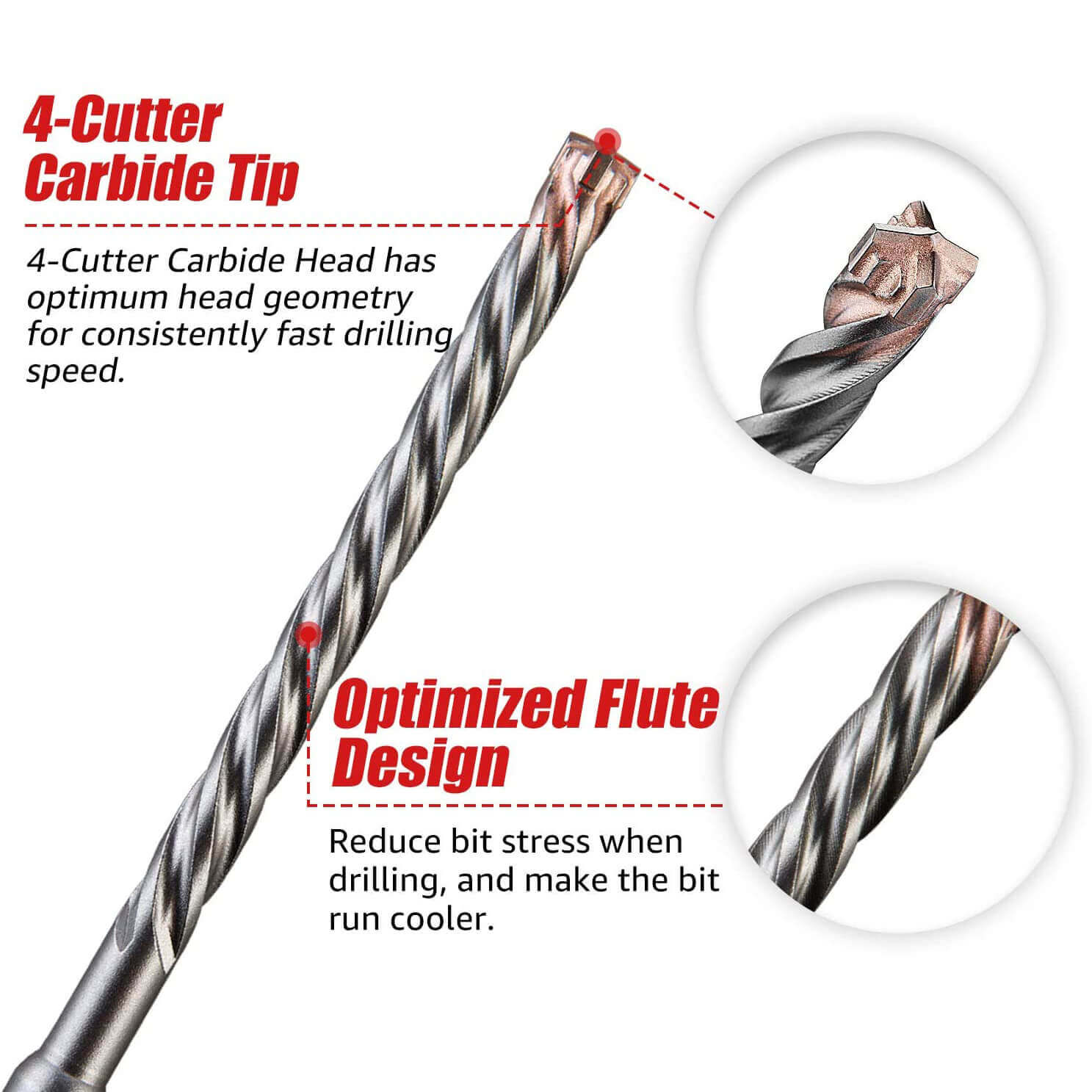

4‑Cutter System Technical Features

- Cutting Angle: 120°‑130° balanced angle for stable cutting

- Flute Pattern: 4‑flute symmetrical distribution, even chip flow

- Guidance: Multi‑edge guidance for higher hole precision

- Drift Resistance: 60% reduction in deflection risk on rebar contact

- Service Life: 40‑70% life improvement in reinforced concrete

Cross‑Head System Technical Features

- Cross Geometry: X‑pattern cutting for maximum guidance

- Anti‑Jam Design: Multiple evacuation paths, lowest jam risk

- Hole Geometry: Roundness error < 0.1mm

- Precision Applications: Chemical anchors, precision mounting preferred

- Impact Distribution: Dispersed impact loading extends tip life

Performance Comparison Matrix

| Performance Metric | 2‑Cutter | 4‑Cutter | Cross‑Head |

|---|---|---|---|

| Speed (Soft Materials) | ★★★★★ | ★★★★ | ★★★ |

| Speed (Hard Materials) | ★★★ | ★★★★ | ★★★★ |

| Hole Precision | ★★★ | ★★★★ | ★★★★★ |

| Drift Resistance | ★★ | ★★★★ | ★★★★★ |

| Jam Resistance | ★★ | ★★★ | ★★★★★ |

| Tool Life | ★★★ | ★★★★ | ★★★★ |

| Cost | ★★★★★ | ★★★★ | ★★★ |

Detailed Application Scenarios

Residential Construction

- Wall Anchoring: 2‑cutter bits for speed and cost control

- Utility Runs: 4‑cutter bits for diameter accuracy

- Finish Work: Cross‑head bits to prevent wall cracking

Commercial Construction

- Structural Frame: 4‑cutter or cross‑head for rebar interference

- Curtain Wall: Cross‑head bits for high precision requirements

- Equipment Foundations: 4‑cutter bits balancing efficiency and stability

Industrial Applications

- Production Drilling: 2‑cutter bits for maximum efficiency

- Precision Installation: Cross‑head bits for accurate positioning

- Harsh Environments: 4‑cutter bits balancing performance and life

Parameter Tuning Guidelines

- 2‑Cutter Bits: 1000‑1200 RPM, light pressure, fast feed

- 4‑Cutter Bits: 800‑1000 RPM, steady feed rate

- Cross‑Head: 600‑800 RPM, precise control

Learn more about specifications: SDS‑Plus Series, SDS‑Max Series.