SDS-Plus Drill Bits

Professional rotary hammer drill bits for concrete and masonry. Complete range Ø5-26mm.

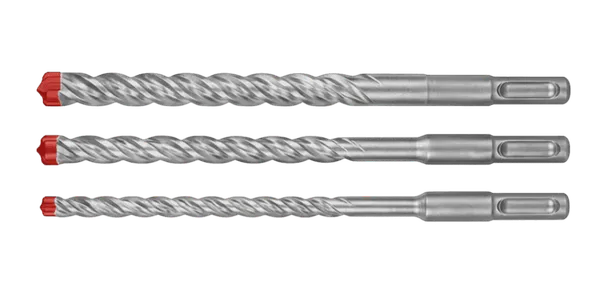

Product Series

Three distinct series designed for different applications and performance requirements

Standard Series

Perfect for everyday concrete drilling. High value, reliable quality.

Pro Series

Enhanced performance with X-type carbide tip for faster drilling and longer life.

4-Cutter Series

Premium 4-cutter head design for precise round holes and rebar cutting capability.

Technical Specifications

Precision manufactured to international standards

Frequently Asked Questions

What diameter range does your SDS-Plus series cover?

Our SDS-Plus series covers Ø5-26mm diameter range, with lengths from 110mm to 1000mm. We offer Standard, Pro, and 4-Cutter series for different applications.

Do you offer OEM/ODM customization for SDS-Plus bits?

Yes, we provide full OEM/ODM services including custom sizes, private label branding, and customized packaging. Minimum order quantities apply based on specifications.

What carbide grade do you use in SDS-Plus drill bits?

We use YG8C German-grade tungsten carbide for optimal hardness and wear resistance. Our Pro series uses enhanced YG8C+ for even better performance.

What certifications do your SDS-Plus products have?

All our SDS-Plus drill bits are ISO 9001 certified, CE marked, and manufactured to ISO 5468 and DIN 8039 international standards.

Are your SDS-Plus bits compatible with major brands?

Yes, our SDS-Plus drill bits are fully compatible with all major rotary hammer brands including Bosch, Makita, DeWalt, Hilti, and Milwaukee.

What does SDS-Plus mean and how is it different from regular drill bits?

SDS-Plus stands for 'Special Direct System' Plus, developed by Bosch in 1975. It's a specialized shank design with grooves that lock into rotary hammer chucks, allowing the bit to slide back and forth during the hammering action.

Key differences from regular drill bits:

• Hammer Action: SDS-Plus bits work with rotary hammers that combine rotation with rapid hammering (up to 4,000 BPM), making them 3-5x faster in concrete than regular bits.

• Quick Change: No chuck key needed - bits insert and lock with a simple push-twist motion.

• Shank Design: 10mm grooved shank vs. smooth cylindrical shank on regular bits.

• Power Transfer: The groove system transfers both rotational and percussive energy efficiently.

Regular drill bits rely solely on rotational cutting and are not designed for impact forces, making them unsuitable for masonry work.

What is the difference between SDS, SDS-Plus, and SDS-Max?

These are three different shank systems designed for different power classes:

SDS-Plus (Most Common):

• Shank Diameter: 10mm

• Bit Range: Ø5-30mm

• Drilling Depth: Up to 1000mm

• Applications: Residential/light commercial concrete, brick, stone

• Machine Type: Compact rotary hammers (3-8 lbs)

• Our Range: Ø5-26mm in Standard, Pro, and 4-Cutter series

SDS-Max (Heavy Duty):

• Shank Diameter: 18mm

• Bit Range: Ø12-80mm

• Drilling Depth: Up to 1500mm+

• Applications: Heavy commercial/industrial concrete, demolition

• Machine Type: Large rotary hammers (12-25 lbs)

Original SDS (Obsolete):

• 10mm shank, predecessor to SDS-Plus, rarely used today

Cannot interchange: An SDS-Plus bit will not fit an SDS-Max chuck and vice versa.

Can I use SDS-Plus bits in a regular drill chuck?

Technically possible with an adapter, but NOT recommended for several critical reasons:

Safety Concerns:

• Regular drills lack the hammer mechanism that SDS-Plus bits are designed for

• The bit may slip or eject under load, causing injury

• Excessive vibration can damage the drill's chuck mechanism

Performance Issues:

• Drilling concrete with rotation-only takes 5-10x longer

• Bit will overheat and wear out prematurely

• Poor hole quality with excessive wobble

Proper Tool Selection:

• For masonry: Use a rotary hammer or hammer drill with SDS-Plus chuck

• For wood/metal: Use standard twist drill bits in regular chuck

• For occasional masonry: Consider hammer drill mode with hex shank masonry bits

If you only have a regular drill and need to drill masonry, use hex shank masonry bits designed for hammer drill mode, not SDS-Plus bits with an adapter.

What materials can SDS-Plus drill bits effectively drill through?

SDS-Plus bits are optimized for masonry materials. Here's what each series handles:

Standard Series (Ø5-16mm):

✓ Concrete (non-reinforced, up to C30/37 grade)

✓ Brick and block (clay, concrete, lightweight)

✓ Natural stone (limestone, sandstone)

✓ Mortar joints

✓ Plaster and render

Pro Series (Ø6-26mm):

✓ Reinforced concrete (up to C40/50 grade)

✓ Hard stone (granite, marble - with caution)

✓ Engineering brick

✓ Thick concrete walls (200-400mm)

4-Cutter Series (Ø16-26mm):

✓ Heavy reinforced concrete (C50/60+ grade)

✓ Steel rebar (can drill through Ø12mm rebar)

✓ Granite and hard natural stone

✓ Concrete with aggregate

NOT suitable for:

✗ Wood (use wood drill bits)

✗ Metal/steel plate (use HSS or cobalt bits)

✗ Tile/ceramic (use diamond core bits)

✗ Glass (requires specialized diamond bits)

For mixed materials (e.g., concrete with embedded conduit), the 4-Cutter series offers the best versatility.

How do I choose between Standard, Pro, and 4-Cutter series?

Selection depends on your application intensity, material hardness, and budget:

Choose Standard Series if:

• Residential DIY or light commercial work

• Drilling non-reinforced concrete or brick

• Hole depth less than 150mm

• Budget conscious (best value)

• Occasional use (1-2 times per week)

• Example: Installing shelves, hanging fixtures, light electrical work

Choose Pro Series if:

• Professional trades (electrician, plumber, HVAC)

• Reinforced concrete or hard materials

• Hole depth 150-400mm

• Daily use requiring durability

• Need faster drilling speed (X-type tip)

• Example: Electrical conduit installation, anchor bolts, commercial fit-outs

Choose 4-Cutter Series if:

• Heavy construction or structural work

• Drilling through rebar without pre-locating

• Large diameter holes (Ø16-26mm)

• Maximum precision and minimal vibration

• Deep holes up to 1000mm

• Example: Structural anchor installation, large pipe penetrations, core drilling

Budget Impact: Standard = 1x, Pro = 1.5x, 4-Cutter = 2.5x base price. However, Pro series often pays for itself in time saved for professionals.

What RPM and drilling technique should I use for concrete?

Optimal Settings for SDS-Plus Drilling:

RPM Guidelines:

• Ø5-10mm bits: 900-1200 RPM

• Ø12-16mm bits: 700-900 RPM

• Ø18-26mm bits: 500-700 RPM

Rule: Larger diameter = Lower RPM. Most rotary hammers auto-regulate, but if adjustable, follow these ranges.

Hammer Rate: 4000-5000 BPM (beats per minute) is optimal for concrete. This is typically fixed on the tool.

Drilling Technique:

1. Start Perpendicular: Hold drill at 90° to surface, apply light pressure to establish the hole

2. Let the Tool Work: Don't force - apply moderate pressure (5-10 lbs) and let the hammer action do the cutting

3. Pecking Motion: For holes deeper than 100mm, withdraw bit every 50mm to clear dust

4. Continuous Cooling: For Ø16mm+ or deep holes, pause every 30 seconds to prevent overheating

Common Mistakes to Avoid:

✗ Excessive pressure (causes premature wear and bit breakage)

✗ Tilting during drilling (creates oval holes)

✗ Drilling continuously without clearing dust (overheats bit and slows progress)

✗ Using rotation-only mode (will destroy the bit)

For reinforced concrete, expect to hit rebar. When you do: maintain steady pressure, don't pull back. The 4-Cutter series handles rebar best.

How can I tell if my SDS-Plus bit is worn out or damaged?

Visual Inspection Signs:

1. Carbide Tip Damage:

• Chipped Edges: Small chips <1mm are acceptable; chips >2mm require replacement

• Rounded Cutting Edges: Tips should be sharp and defined, not rounded

• Missing Carbide: If any carbide insert is completely gone, replace immediately

• Uneven Wear: One side worn more than another (indicates drilling at an angle)

2. Shank Wear:

• Groove Damage: SDS slots should be clean and well-defined

• Excessive Play: Bit wobbles in chuck even when locked (shank worn down)

• Scoring/Gouges: Deep scratches in the shank area

3. Flute Condition:

• Clogged Spirals: Concrete buildup that won't clean off

• Spiral Deformation: Bent or collapsed flutes

Performance Indicators:

• Drilling Speed: Takes 2x+ longer than when new

• Dust Color: Black dust indicates bit overheating (vs. gray/white concrete dust)

• Vibration: Excessive shaking or chattering during use

• Drill Behavior: Tool struggles, bogs down, or stalls frequently

• Hole Quality: Rough, oversized, or out-of-round holes

When to Replace:

• Standard Series: After 80-150 holes (Ø10mm x 100mm in C30 concrete)

• Pro Series: After 200-350 holes

• 4-Cutter Series: After 300-500 holes

Pro Tip: Keep a worn bit as a 'starter' - use it to establish the hole, then switch to a sharp bit to complete. This extends sharp bit life by 30-40%.

How should I maintain and store SDS-Plus drill bits?

Proper Maintenance Routine:

After Each Use:

1. Dust Removal: Use compressed air or stiff brush to clear concrete dust from flutes and SDS grooves. Dust left in grooves causes premature shank wear.

2. Wipe Down: Clean with dry cloth. For wet drilling, wipe thoroughly to prevent rust.

3. Inspect: Quick visual check for carbide chips or damage.

Weekly (for professionals):

1. Deep Clean: Soak in degreaser for 10 minutes, scrub flutes with wire brush

2. Lubricate Shank: Apply light machine oil or anti-seize compound to SDS grooves (NOT the carbide tip)

3. Check Chuck: Clean the rotary hammer's SDS chuck; blow out dust from groove slots

Storage Best Practices:

1. Organization:

• Use indexed bit case or wall-mounted holder (prevents bits from rolling/falling)

• Store vertically with carbide tip up (prevents tip damage)

• Separate by size for quick access

2. Environment:

• Dry location with <60% humidity

• Avoid temperature extremes (concrete dust absorbs moisture)

• Keep away from corrosive chemicals

3. Protection:

• Use rubber tip protectors for carbide heads (especially during transport)

• Never throw loose bits in toolbox (causes chipping)

• For long-term storage (3+ months), coat shank with rust preventive

What NOT to Do:

✗ Leave bit mounted in hammer overnight (wears chuck)

✗ Store wet bits (causes rust on shank)

✗ Stack bits on top of each other (damages carbide)

✗ Use WD-40 as lubricant (attracts dust)

Proper care can extend bit life by 50-70% and maintain optimal performance.

What certifications and quality standards do your SDS-Plus bits meet?

Our Manufacturing Standards:

ISO 9001:2015 Certified:

• Full quality management system certification

• Covers design, production, testing, and delivery

• Annual third-party audits by accredited bodies

• Ensures consistent manufacturing processes

Product Standards Compliance:

• ISO 5468: Rotary hammer drill bits with hardmetal tips (dimensional accuracy, shank tolerances)

• DIN 8039: German industrial standard for SDS-Plus shank dimensions and groove specifications

• Ensures perfect fit in all SDS-Plus chucks from major brands

Safety Certifications:

• CE Marking: European Conformity for safety, health, and environmental standards

• Covers carbide tip bonding strength, shank material properties, and safe operational limits

Material Certifications:

• Carbide Grade YG8C: Certified tungsten carbide composition (8% Cobalt, 92% Tungsten Carbide)

• Steel Body: 40Cr chrome-molybdenum alloy steel, heat-treated to HRC 48-52

• Brazing Quality: Silver-copper brazing alloy meeting AWS A5.8 standards

Testing Procedures:

• Every production batch: Carbide hardness test (HRA 89-92)

• Random sampling: Drilling endurance test (minimum 100 holes in C30 concrete)

• 100% inspection: Shank dimensional check (groove depth, diameter tolerance ±0.02mm)

Documentation Available:

• Material test certificates (upon request for large orders)

• CE Declaration of Conformity

• ISO 9001 certificate (provided with first order)

• Third-party lab test reports (available for OEM customers)

This comprehensive quality system ensures every bit meets professional-grade standards.

What is your MOQ for custom OEM orders?

Our MOQ varies based on customization level:

Standard Products (Our existing sizes):

• Minimum: 500 pieces per size

• Mixed sizes allowed (e.g., 200pcs Ø8mm + 300pcs Ø10mm)

• Your brand packaging only

• Lead time: 15-20 days

• Typical for: Retailers, distributors entering market

Custom Packaging Only:

• Minimum: 1,000 pieces total

• Can mix any standard sizes

• Custom box design, insert cards, labels with your logo

• Packaging design service included

• Lead time: 20-25 days

• Typical for: Established brands, promotional sets

Custom Specifications:

• Minimum: 2,000 pieces per specification

• Includes: Non-standard lengths, diameters, or carbide grades

• Requires: Technical drawings and sample approval

• Lead time: 30-40 days (includes mold/tooling setup)

• Typical for: Specialized applications, private label brands

Full OEM Partnership:

• Minimum: 5,000 pieces initial order

• Includes: Complete specification customization, packaging design, co-branding options

• Benefits: Exclusive designs, protected territory, marketing support

• Lead time: 40-50 days

• Typical for: Major distributors, tool brands

Sample Policy:

• Free samples: 2-3 pieces of standard products (you pay shipping)

• Custom samples: $50-150 per specification (refundable on order >2000 pcs)

• Sample delivery: 5-7 days

Price Benefits by Volume:

• 500-999 pcs: Standard pricing

• 1,000-4,999 pcs: 8-12% discount

• 5,000-9,999 pcs: 15-18% discount

• 10,000+ pcs: 20-25% discount + free freight

Payment Terms: 30% deposit, 70% before shipment (L/C available for orders >$10,000)

Need Custom Specifications?

We offer OEM/ODM services for custom sizes, branding, and packaging.