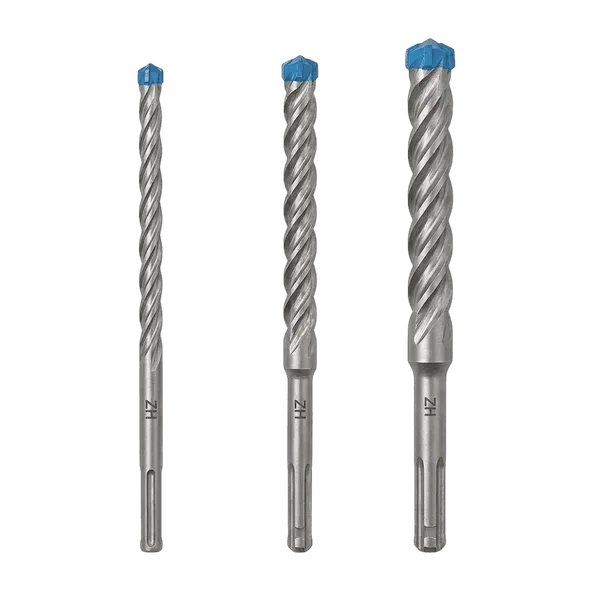

SDS-Max Heavy Duty

Professional heavy-duty rotary hammer drill bits for industrial concrete drilling. Complete range Ø12-40mm.

Heavy Duty Product Series

Three heavy-duty series designed for industrial applications and extreme conditions

Construction Duty

General construction grade for common drilling in reinforced concrete and hard materials.

Industrial Duty

Industrial-grade performance for larger diameters, deeper holes and extended operation.

Extreme Duty

Maximum strength for extreme conditions and extra-large diameter drilling.

Technical Specifications

Heavy-duty design with precision manufacturing to industrial standards

Frequently Asked Questions

What is the difference between SDS-Plus and SDS-Max?

SDS-Max uses an 18mm shank vs 10mm for SDS-Plus, delivering 3-5x more impact energy. SDS-Max is designed for heavy-duty industrial applications with diameters Ø12-40mm.

What diameter and length range does SDS-Max cover?

Our SDS-Max series covers Ø12-40mm diameter with lengths from 200mm to 1200mm. We offer Construction, Industrial, and Extreme Duty grades.

Can SDS-Max bits drill through rebar?

Yes, our Industrial and Extreme Duty series feature reinforced carbide tips designed to handle rebar encounters in reinforced concrete applications.

What industries use SDS-Max drill bits?

SDS-Max is widely used in infrastructure construction, bridge engineering, tunnel boring, foundation work, and professional demolition projects.

Do you supply SDS-Max bits for OEM customers?

Yes, we provide full OEM/ODM services for SDS-Max products including custom specifications, branding, and bulk packaging for industrial distributors.

What is the difference between YG8C and YG11C carbide grades?

YG8C is the standard grade for general construction drilling, offering a good balance of hardness and impact resistance. YG11C is a premium industrial grade with higher cobalt content, providing 30-50% longer life and better thermal stability for continuous heavy-duty drilling in high-density reinforced concrete.

What are the recommended drilling techniques and RPM for SDS-Max bits?

SDS-Max bits require high impact energy but lower rotation speed than smaller bits.

Recommended RPM values:

• Ø12-18mm: 350-450 RPM

• Ø20-32mm: 250-350 RPM

• Ø35-40mm: 150-250 RPM

Technique tips: (1) Let the machine do the work - do not apply excessive feed pressure, (2) Clean the hole frequently by pulling the bit slightly back, (3) Stop immediately if you hit solid steel rebar to prevent tip overheating (unless using Extreme Duty series).

How do I know when to replace my SDS-Max drill bit?

Replace your bit if you notice: (1) The carbide tip is rounded or significantly chipped, (2) The drill speed drops by more than 50% under normal pressure, (3) The hole diameter becomes undersized (cannot fit the anchor), or (4) Excessive vibration or heat during operation. A bit with a missing carbide tip must be retired immediately to prevent damage to the rotary hammer.

How should I maintain and store my SDS-Max bits?

(1) Grease the shank: Always apply a small amount of specialized grease to the SDS-Max shank before insertion to minimize friction and wear on the tool holder. (2) Clean after use: Remove concrete dust and debris. (3) Moisture protection: Apply a light coat of anti-rust oil or WD-40 for long-term storage in humid environments. (4) Store upright: Avoid dropping bits which can cause carbide micro-fractures; use a dedicated kit box or wall rack.

Are Zhonghuan SDS-Max bits compatible with Bosch and Hilti hammers?

Yes, our SDS-Max bits are manufactured to strict ISO 5468 and DIN 8039 standards. The 18mm shank with three open and two closed grooves is 100% compatible with all major brands including Bosch (GSH/GBH series), Hilti (TE-Y), Makita (HR), DeWalt, and Milwaukee rotary hammers.

When should I choose Construction vs Industrial vs Extreme Duty series?

Construction Duty: Best for residential/light commercial work (Ø12-25mm).

Industrial Duty: Heavy infrastructure, bridges, and deep foundations (Ø18-32mm).

Extreme Duty: Demolition, large structural modifications, and drilling in extra-hard or heavily reinforced concrete (Ø25-40mm).

Consider the Extreme Duty if you perform continuous daily drilling for over 4 hours.

What is the MOQ and lead time for custom SDS-Max orders?

For standard specifications, the MOQ is 100-200 pieces per size. For custom lengths or branding (OEM), the MOQ starts at 500 pieces. Lead time is typically 25-35 days for mass production. We also offer trial orders for qualified industrial distributors to verify quality.

Need Heavy Duty Drilling Solutions?

We provide professional heavy-duty drill bit customization for industrial applications and special working conditions. Our technical team offers optimal solutions.