Why Maintenance is Not a Chore

Let’s be honest. At the end of a long, dusty day on the job, the last thing anyone feels like doing is cleaning their tools. It's tempting to just toss your SDS drill back in the truck and deal with it tomorrow. I’ve been there. But I’ve also learned the hard way that a few minutes of care today can save you hours of headaches and hundreds of dollars tomorrow. Think of your SDS drill not as a disposable commodity, but as a key member of your team—your money-maker. Proper maintenance isn't a chore; it's a discipline. It’s the difference between a tool that dies an early death and a trusted workhorse that performs reliably for years. It's about respecting the tools that help you earn a living.

The 5-Minute End-of-Day Ritual

This is the most important habit you can build. It takes less time than it takes to drink a cup of coffee. First, grab an air compressor or a stiff brush and blow out all the dust from the drill's vents, chuck, and especially from the flutes of your drill bit. Concrete dust is incredibly abrasive and acts like sandpaper on the internal components of your drill. Getting it out at the end of each day is non-negotiable.

Next, take a clean rag and wipe down the housing of the drill and the shank of the bit. Give the bit a quick visual inspection. Is the carbide tip chipped? Is it starting to look more rounded than sharp? Being honest about the condition of your bits will save you time and effort in the long run. A dull bit doesn't just drill slower; it puts a massive strain on your drill's motor and hammering mechanism.

The Weekly Deep Clean: Grease and Gratitude

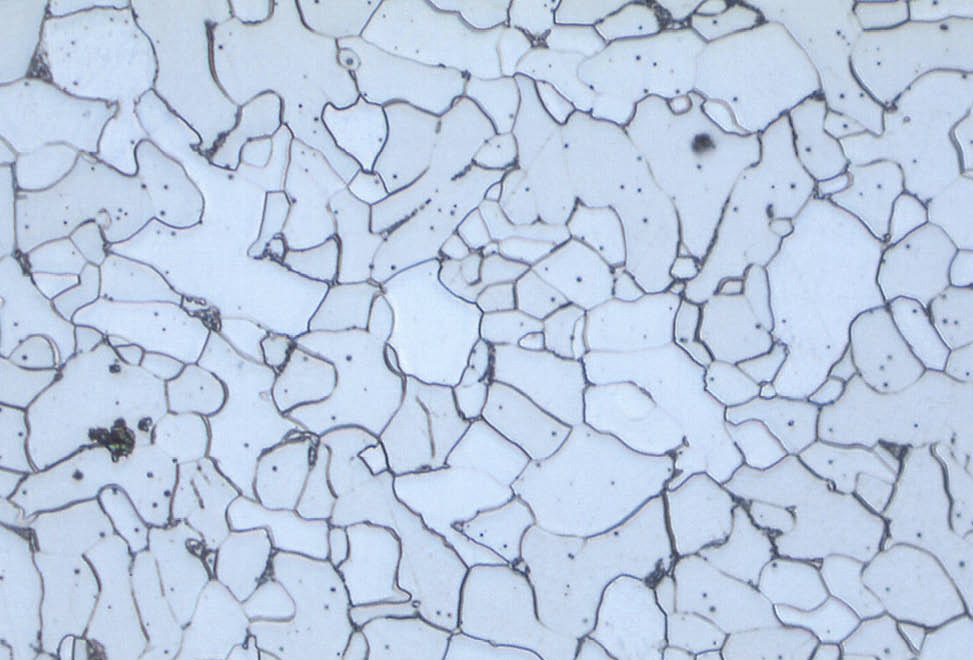

Once a week, or after a particularly grueling job, it’s time to show your tools a little extra love. This is where grease comes in. The SDS chuck is a marvel of engineering, but it relies on clean, lubricated surfaces to work properly. Pop the boot or cap off the chuck (check your manual for specifics) and use a small brush to clean out any old, gunked-up grease and concrete dust.

Once it's clean, apply a small amount of fresh, high-quality grease. Don't go crazy here; too much grease will just attract more dirt. You want just enough to coat the moving parts. While you're at it, apply a very thin film of grease to the shank of your drill bits. This isn't just for lubrication; it creates a barrier that makes it much harder for dust to work its way into the chuck. This simple weekly ritual keeps the hammering action smooth and powerful and dramatically extends the life of the most critical part of your drill.

A Good Home: Storing Your Tools for the Long Haul

How you store your drill is just as important as how you clean it. Tossing it into the back of a damp truck bed is a recipe for rust and corrosion. Your drill's original case isn't just for looks; it's designed to protect it from impacts and moisture. Use it. Store your tools in a dry, secure place where they aren't going to get knocked around.

This is especially true for your bits. Don't just throw them in a bucket together where they can bang against each other. That's a surefire way to get chipped carbide tips. Keep them in a bit case or a roll-up pouch. It not only protects them but also keeps them organized, so you're not digging around for the right size when you should be working. A little organization goes a long way in protecting your investment.

Listening to Your Tool: What to Do When It Talks Back

Your drill will tell you when something is wrong; you just have to learn to listen. Is the drilling speed slower than it used to be? That's the most common complaint, and 90% of the time, the culprit is a dull bit. Don't blame the drill; thank it for telling you it's time for a new bit. The other 10% of the time, it's a sign that your chuck is dirty and needs a good cleaning and greasing.

If you start to feel an unusual vibration or hear a new, grinding noise, stop immediately. That's a more serious cry for help. It could be a sign of a loose component or a failing internal part. Don't try to be a hero and push through it. You'll likely turn a minor repair into a catastrophic failure. Power it down and get it to a qualified service technician. A well-maintained tool talks to you in whispers; a neglected tool screams.

The Craftsman’s Mindset

In the end, it comes down to a simple choice. You can treat your tools like they're disposable, or you can treat them like the valuable assets they are. A true craftsman understands that their tools are an extension of their skill. Taking care of them isn't a burden; it's part of the job. It's a reflection of the pride you take in your work. So, take those five extra minutes at the end of the day. Your tools—and your wallet—will thank you for it.