The Enemy: Know Your Corrosion

We've all seen it. A brand-new tool, gleaming and perfect, left out in the rain for one night and already showing the first tell-tale signs of rust. Corrosion is the silent killer on any job site. It doesn’t just make your tools look bad; it actively weakens them from the inside out, compromising their strength, causing parts to seize up, and ultimately leading to failure—often at the worst possible moment. It’s not just about rain, either. On an industrial site, you're fighting a multi-front war against chemical fumes, salt spray, and abrasive dust.

It's crucial to know what you're up against. Sometimes it's a uniform attack, where the whole surface slowly degrades. More dangerous is pitting corrosion, which acts like a cancer, creating deep, localized holes that can compromise the structural integrity of a tool. And then there’s stress corrosion, a particularly nasty villain where a tool under heavy load becomes far more susceptible to chemical attack, leading to sudden, brittle failure. Understanding these enemies is the first step to defeating them.

Our Shield: The Science of Our Coatings

You can't fight a chemical war with brute force alone; you need advanced armor. That's what our proprietary coating systems are. We think of it as a multi-layered shield, where each layer has a specific job to do. It all starts with a perfectly prepared surface, because a coating is only as good as its bond to the steel beneath it. We use a combination of mechanical and chemical treatments to create the ideal foundation.

The first layer is a primer that acts like a tenacious glue, ensuring the subsequent layers have an unbreakable grip. Next comes the heart of our defense: a barrier layer, often a specialized ceramic or polymer, that is impermeable to the corrosive molecules you'll find on site. Finally, we apply a tough, functional topcoat. Depending on the tool's intended use, this could be anything from a hard, wear-resistant chrome to a chemically inert fluorocarbon. This entire process, from PVD to thermal spraying, is done in a controlled environment to ensure a flawless, uniform shield that’s ready for the front lines.

Trial by Fire (and Salt): How We Test for Toughness

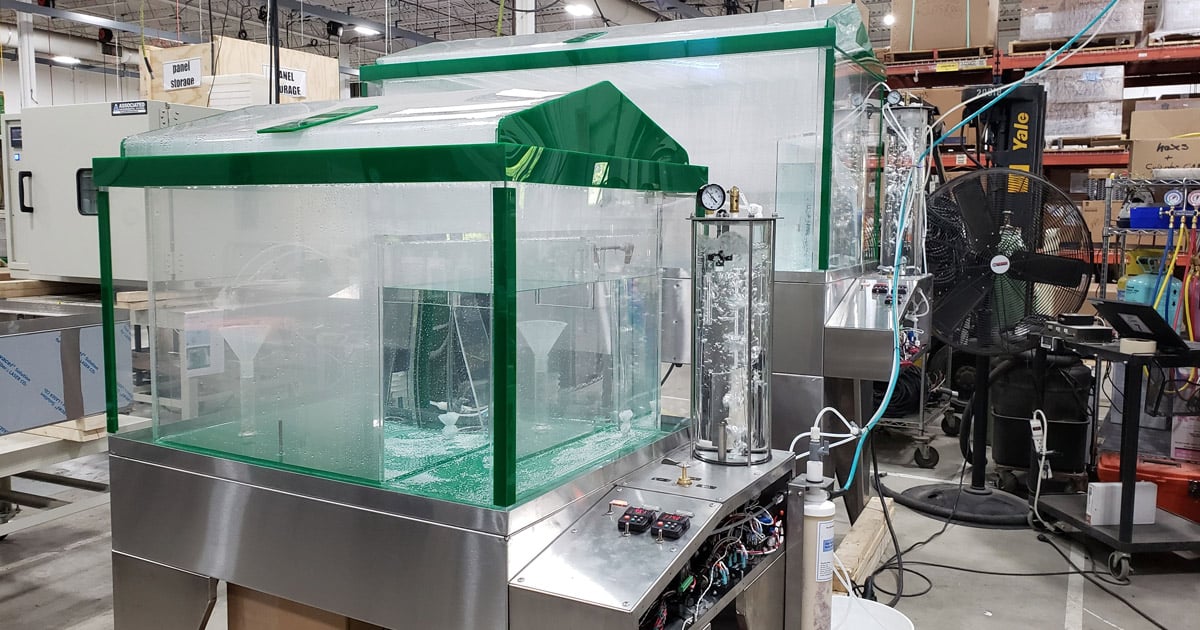

Making a claim is easy; proving it is hard. That's why we put our coatings through hell before they ever get to you. Our in-house testing lab is designed to simulate the most corrosive environments on earth. The star of the show is our salt spray chamber. We blast our coated tools with a super-saturated salt fog for over 500 continuous hours—a brutal test that simulates years of exposure in a marine or de-icing environment.

But we don't stop there. We run cyclic corrosion tests, alternating between wet, dry, hot, and cold cycles to mimic the reality of a job site. We use electrochemical testing to get a rapid, real-time measure of how the coating is holding up at a molecular level. We check the adhesion with brutal pull-off tests, ensuring the coating won't chip or flake under stress. Only the coatings that survive this gauntlet are worthy of protecting a Zhonghuan tool.

On the Front Lines: Real-World Scenarios

Different battlefields require different armor. For a chemical plant, where tools are constantly exposed to aggressive acids and bases, our fluorocarbon and ceramic coatings provide a nearly impenetrable, chemically inert barrier. We had a client in a processing plant whose tools were failing in a matter of weeks. After switching to our coated tools, they're now getting years of service, saving them a fortune in replacement costs and downtime.

For marine applications—think offshore rigs or coastal bridge repair—the enemy is salt. It's relentless. Here, our zinc-aluminum composite coatings act as a 'sacrificial' layer. The coating corrodes first, protecting the steel underneath. Paired with a tough polyurethane topcoat to ward off UV rays and abrasion, it's a system that can withstand a decade of punishment from the sea and sun without breaking a sweat. Choosing the right shield for the right fight is critical.

Protecting the Shield: How to Care for Coated Tools

Our coatings are tough, but they're not invincible. The key to long life is to treat the coating with the same respect you give the tool itself. At the end of the day, wipe down the tool to remove any corrosive residues, chemicals, or salt. Don't use a wire brush or abrasive pads, as that can scratch the coating and create a foothold for corrosion. A simple rag and some water or a mild solvent is all you need.

Periodically, give your coated tools a quick visual inspection. If you see a deep scratch or a chip that has penetrated the coating down to the bare metal, it's important to act. A small touch-up with an appropriate high-quality paint or sealant can stop corrosion before it has a chance to creep under the coating and cause real damage. Your tool's armor is only as strong as its weakest point.

The Bottom Line

Investing in a tool with a high-quality, corrosion-resistant coating isn't an expense; it's an investment in uptime, safety, and professionalism. It means fewer tool failures, less time wasted on maintenance and replacements, and a lower total cost of ownership over the life of the tool. It's about having confidence that your tools will be ready to work when you are, no matter how nasty the job site gets. Don't let the silent killer of corrosion eat into your profits. Fight back with the right armor.