Key Challenges

- Brutal deadline with downtown noise/hour restrictions

- Dense 32mm rebar in C40 high‑strength concrete

- Adjacent building protection demands surgical demolition

- High downtime and low throughput with conventional tools

Solution Value

- High‑impact SDS‑Max + specialized chisels for rapid break‑out

- Low‑vibration, adjustable impact for safe, controlled cuts

- On‑site training + monitoring to drive a predictable cadence

- Massively reduced downtime; 40%+ overall productivity gain

The Mission: A Downtown High-Rise

The call came in on a Monday morning. A major contractor had landed the job of demolishing a 20-story commercial building in a crowded city center. The catch? The timeline was aggressive. They had six months on paper, but the owner was pushing hard to get the site cleared for a new development, and penalties for delays were steep. This wasn't just a demolition job; it was a race against time. The building was a beast: 15,000 square meters of heavily reinforced, high-strength concrete. This was going to be a street fight, and the contractor needed to know their tools wouldn't let them down.

The Squeeze: Tough Concrete and a Ticking Clock

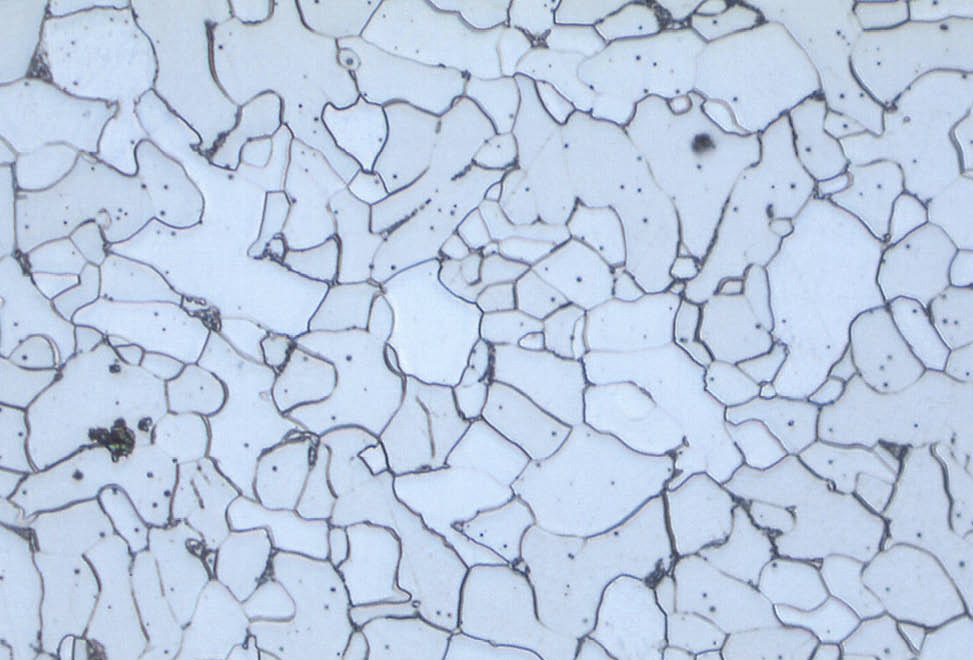

The project manager laid it out for us. The building was constructed in the late 80s, a period when they weren't shy with the rebar. We were looking at dense cages of 32mm steel entombed in C40-grade concrete that had been curing for over three decades. It was going to be tough, slow going with conventional tools. To make matters worse, the building was sandwiched between two active office buildings. This meant precision was paramount. They couldn't just swing a wrecking ball; they needed surgical demolition, which is always slower.

On top of the technical challenges, the clock was their biggest enemy. The city had imposed strict work hours and noise ordinances, and the weather forecast showed a shorter-than-usual window for favorable demolition conditions. Every hour of downtime, every broken tool, every moment of inefficiency would put them further behind schedule and deeper into penalty territory. They weren't just fighting the building; they were fighting the calendar.

The Playbook: The Right Tools and the Right Team

This was a perfect job for our SDS-Max system. We didn't just sell them a pallet of tools; we embedded one of our senior field support specialists with their team. After walking the site and analyzing the blueprints, we put together a comprehensive playbook. The workhorse would be our heavy-hitting SDS-Max demolition hammers, which deliver a bone-rattling 17 joules of impact energy—enough to make that C40 concrete think twice.

We paired these hammers with a full suite of our specialized chisels: wide flat chisels for scaling large surfaces, pointed bull-point chisels for punching through thick sections, and precision gouging chisels for the delicate work around the adjacent buildings. The key was having the right tool for each specific task, and the training to use it effectively. Our specialist spent two full days with their crews, not just showing them how to use the tools, but how to 'read' the concrete and let the tool do the work. It was about working smarter, not just harder.

Execution: How It All Went Down

With the playbook in hand, the crew went to work. They adopted a top-down, floor-by-floor strategy. The real game-changer was how the SDS-Max tools allowed them to work with a level of precision that larger equipment could never match. They could carve out sections of the building with surgical accuracy, ensuring no damage to the neighboring structures. Our field specialist remained on-site for the first week, helping them fine-tune their approach, optimize the use of different chisels, and establish a rhythm.

Instead of just brute-force hammering, the crew learned to use the tools to find the weaknesses in the structure, making controlled cuts and breaks that brought down huge sections of concrete with surprising ease. The low-vibration design of our hammers meant the operators could work longer shifts with less fatigue, and the noise levels were low enough to keep the neighbors—and the city inspectors—happy. It was a symphony of controlled destruction, and it was running like clockwork.

The Payoff: Smashing Expectations

The numbers speak for themselves. The project, originally slated for a nail-biting six months, was completed in just 4.2 months. That’s nearly two months ahead of schedule, a massive win for the contractor and the property owner. The demolition crews were working 40% more efficiently than they had projected with their old methods. But the most telling statistic for us was this: downtime due to tool failure dropped by a staggering 85%. Our tools just kept running, day in and day out.

The financial impact was just as dramatic. The increased efficiency meant a 30% reduction in labor costs. And because our tools were so durable, the contractor spent 25% less on tool rental and replacement than they had budgeted. In total, they came in around 2 million yuan under budget. All this, while maintaining a perfect safety record and keeping the demolition precision within a tight 5cm tolerance. It wasn't just a win; it was a blowout.

What We Learned: Lessons from the Field

This project was a powerful reminder of a lesson we preach every day: the right tool is only part of the equation. The real magic happened when the right tools were paired with the right strategy and the right training. The contractor's willingness to embrace a new approach and our ability to provide hands-on, expert support created a partnership that was far more effective than either of us could have been on our own.

It also reinforced the importance of planning. The week we spent on site before the first hammer swung was the most valuable week of the entire project. It allowed us to tailor the tool selection, anticipate challenges, and ensure every member of the crew was confident and competent. A little bit of planning on the front end saved them a massive amount of time and money on the back end.

More Than a Tool Supplier

This case study is a perfect example of how we see our role in the industry. We're not just here to sell you tools. We're here to be your partner in problem-solving. We're here to bring our decades of engineering and field experience to your toughest challenges. This project's success wasn't just about the power of our SDS-Max hammers; it was about the power of collaboration.

When you're facing a tough job with a tight deadline, you need more than just good tools; you need a team in your corner. That's who we are. We're ready to roll up our sleeves, get our boots dirty, and work with you to develop a winning strategy. Your success is our success.