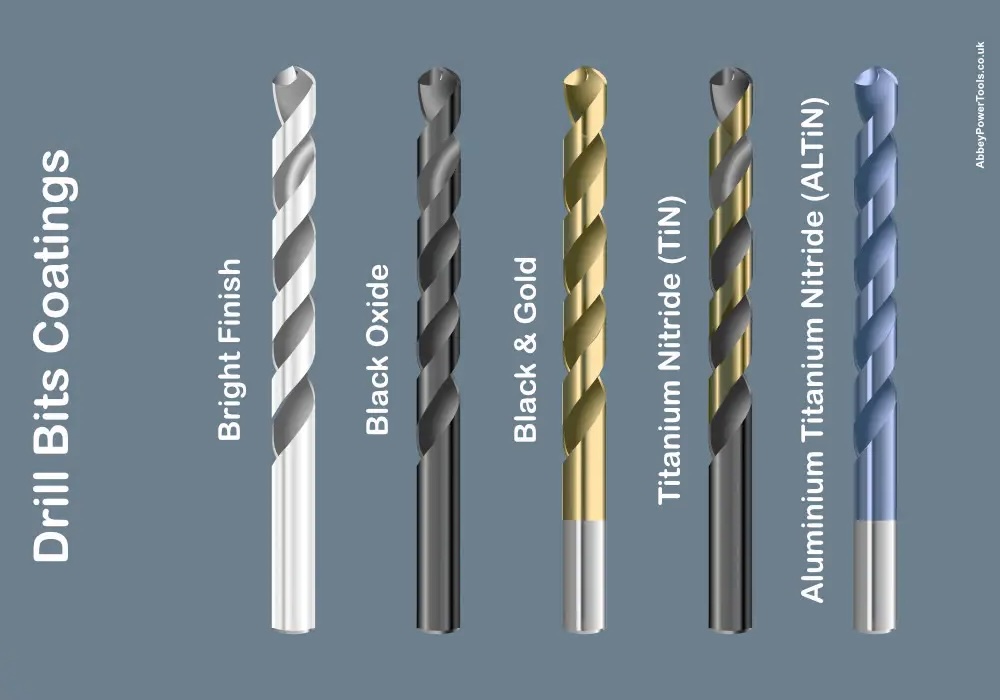

Coating Technologies Deep Dive

Drill bit coating technology is a critical performance enhancement method. Different coating systems excel in corrosion resistance, wear protection, and high‑temperature stability. Proper coating selection and application can dramatically extend tool service life.

Metallic Coating Systems

- Nickel Plating: 5‑15μm thickness, HV500‑600 hardness, excellent general corrosion resistance

- Chrome Plating: 10‑25μm thickness, HV800‑1000 hardness, superior wear and corrosion resistance

- Zinc‑Aluminum Composite: 20‑50μm thickness, sacrificial anode protection for marine environments

- Nickel‑Phosphorus Alloy: 15‑30μm thickness, amorphous structure, uniform protection

Ceramic Coating Systems

- Aluminum Oxide: HV1500‑2000 hardness, outstanding wear resistance

- Zirconia Ceramic: Better toughness, strong impact crack resistance

- Titanium Carbide: Extreme hardness, suitable for severe wear environments

- Composite Ceramics: Multi‑layer structure balancing hardness and toughness

Polymer Coating Systems

- Epoxy Resin: Strong adhesion, good chemical stability

- Polyurethane: Excellent flexibility, superior impact resistance

- Fluorocarbon: Maximum chemical inertness, outstanding self‑cleaning

- Nano‑Composites: Enhanced matrix performance, multi‑functional protection

Environmental Adaptation Selection Guide

Marine & Coastal Environments

- Salt Spray Concentration: High salt areas require nickel+ceramic composite coatings

- UV Exposure: Outdoor applications need UV‑stable topcoat systems

- Humidity Control: Select hydrophobic coatings to reduce moisture penetration

- Test Standards: ASTM B117 salt spray test > 500 hours

Chemical & Acid‑Base Environments

- Acidic Media: Fluorocarbon or modified epoxy, pH 2‑6 suitable

- Alkaline Media: Ceramic or nickel‑based coatings, pH 8‑12 suitable

- Organic Solvents: Fluorocarbon coatings, excellent solvent barrier properties

- High‑Temp Chemical: Ceramic coatings, temperature resistance up to 800°C

High‑Temperature & Wear Environments

- Dry Cutting: Ceramic coating + optimized geometry to reduce friction heating

- Continuous Operation: Multi‑layer systems, base heat dissipation + surface wear resistance

- Abrasive Environments: Hard ceramic coatings, HV > 1500

Coating Quality Control & Testing Standards

Coating Performance Testing

- Adhesion Testing: Pull‑off test > 15 MPa, cross‑cut test Grade 0

- Hardness Testing: Vickers hardness, different standards for different coatings

- Thickness Testing: Eddy current or magnetic gauging, uniformity ± 10%

- Porosity Testing: Electrochemical impedance to assess coating density

Corrosion Resistance Evaluation

- Salt Spray Testing: ASTM B117, 500‑1000 hours without corrosion

- Cyclic Corrosion: Simulate real environments, wet‑dry cycle testing

- Electrochemical Testing: Polarization curves for rapid corrosion assessment

- Immersion Testing: Long‑term immersion in specific media, chemical stability evaluation

Coating Process Control Points

- Surface Preparation: Blast to Sa2.5 grade, roughness Ra 3‑6μm

- Application Environment: Temperature 20‑25°C, humidity < 60%

- Curing Conditions: Set temperature and time per coating type

- Quality Inspection: Batch sampling, establish quality records

Coating Failure Modes & Prevention

- Blistering/Peeling: Inadequate prep → Strict process adherence

- Pinhole Defects: Poor environment → Control temperature/humidity

- Thickness Variation: Process drift → Strengthen monitoring

- Poor Adhesion: Substrate contamination → Enhanced cleaning validation

Coating Maintenance & Care

- Post‑Use Cleaning: Promptly remove corrosive residues

- Storage Environment: Dry, ventilated, prevent collision scratches

- Regular Inspection: Monitor coating integrity, timely repair

- Usage Records: Maintain coated tool service logs