Key Challenges

- Extreme demands on durability in high‑strength concrete and abrasive media

- Thermal softening and fatigue cracking under long continuous impact

- Balancing hardness, toughness and wear resistance simultaneously

- Bridging lab metrics with real job‑site outcomes

Solution Value

- Alloy recipe + heat‑treat synergy yields tempered martensite with fine carbides

- Targets: HRC 58‑62 / Impact ≥15J / Fatigue 10^6 cycles; 3‑5× field life

- SEM/EDS/XRD tri‑link between microstructure, lab performance and job‑site KPIs

- Standardized process improves batch consistency and reduces risk

More Than Just Steel: An Introduction

Pick up one of our demolition chisels. Feel the weight of it in your hand. That solid, reassuring heft isn't just dead weight—it's potential energy, waiting to be unleashed. But what you're holding is more than just a hunk of sharpened steel. It's the culmination of a long and fiery journey, a story written in the language of metallurgy, precision engineering, and a relentless pursuit of performance. We're not just making tools; we're crafting instruments of controlled destruction, designed to withstand the most brutal conditions on a job site. This is the story of how we turn raw alloys into the heart of your demolition work, a tool so tough, it feels like an extension of your own will.

The Recipe: Crafting the Perfect Alloy

Think of our steel as a high-performance recipe, where every single ingredient is measured with obsessive precision. We start with a base of high-carbon tool steel. The carbon is the backbone, providing the raw hardness needed to bite into concrete and asphalt. But hardness alone is brittle. That's where the rest of our 'spice blend' comes in. We introduce a healthy dose of chromium, not just for that gleam, but to create a microscopic shield against the corrosive environments of a construction site.

But we don't stop there. A touch of molybdenum is our secret weapon for high-temperature strength, ensuring the chisel point doesn't soften when the work gets intense. Then comes vanadium, a fascinating element that acts like a grain refiner, forcing the steel's internal structure to be finer and more robust, which is key to preventing the propagation of micro-cracks that lead to failure. It’s a delicate balancing act. Too much of one element, not enough of another, and the whole formula is off. It has taken us years of testing and refinement to perfect this recipe, creating a steel that is not just hard, but tough, resilient, and ready for anything.

Trial by Fire: The Art of Heat Treatment

Having the perfect recipe is only half the battle. The real magic happens in the forge. Our heat treatment process is an aggressive, multi-stage ritual that unlocks the true potential of our steel alloy. Think of it as a workout for the metal. We begin with a slow, gentle preheat, like a warm-up, to relieve any internal stresses from the forging process. Then, we crank up the heat, taking the steel into the searing 850-950°C range, a process called austenitization. This is where the internal structure of the steel completely reorganizes itself into a new, uniform state.

The critical moment is the quench. From the peak temperature, the steel is plunged into a specialized oil bath, a violent, rapid cooling that shocks the microstructure into a new, hardened state called martensite. It’s this shock that gives the chisel its incredible hardness. But pure martensite is too brittle, like glass. So, the final step is tempering. We gently reheat the chisel to a much lower temperature, a precise 'soak' that relieves the brittleness and imparts the crucial toughness that allows the tool to absorb thousands of high-impact blows without shattering. Our control over this process is surgical, with temperature tolerances of just ±3°C. It's this fanatical attention to detail that creates a tool with the perfect balance of hardness and resilience.

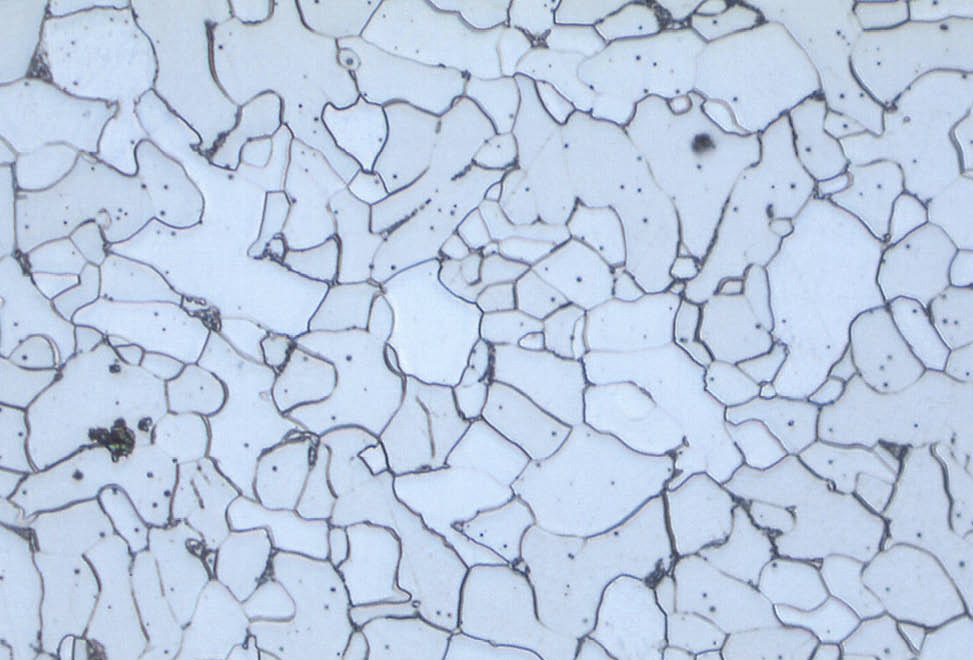

A Look Under the Hood: The Microscopic Story

To the naked eye, it's just a piece of steel. But put it under a powerful electron microscope, and a whole new world is revealed. This is where we can see the direct results of our meticulous alloying and heat treatment. We're looking for a very specific landscape: a dense, uniform matrix of tempered martensite. This is the workhorse structure that provides the tool's strength. But we're also looking for what's *not* there—specifically, we want to see less than 5% retained austenite, which can compromise the dimensional stability of the tool over time.

Using techniques like Scanning Electron Microscopy (SEM) and Energy Dispersive Spectroscopy (EDS), we can zoom in even further. We can see how the carbides, formed by the vanadium, are distributed throughout the matrix like tiny, wear-resistant diamonds. We can verify that the grain structure is incredibly fine and uniform—an ASTM 8-10 grade, for the technically inclined—which is a direct indicator of a tough, fracture-resistant tool. It’s this deep, almost obsessive, analysis that allows us to move beyond guesswork. We don’t just *hope* our chisels are tough; we have the microscopic evidence to prove it.

The Ultimate Test: From the Lab to the Job Site

Microscopes and lab tests are one thing, but the real test is how a tool holds up under punishment. This is where we separate the contenders from the pretenders. In our R&D facility, we subject our chisels to a gauntlet of brutal tests that simulate years of abuse in a matter of hours. We use a Rockwell hardness tester to ensure every single chisel tip meets our exacting HRC 58-62 standard—the sweet spot for edge retention and impact resistance. We smash them in Charpy impact testers, delivering bone-jarring blows to guarantee they can withstand accidental drops and off-angle strikes.

But the test I'm most proud of is our fatigue life cycle test. We lock a chisel into a machine that slams it against a hardened steel anvil, over and over again, for millions of cycles. It’s loud, it’s violent, and it’s the ultimate proof of our design. A good chisel won’t just survive this; it will endure with minimal wear. We measure everything—wear rate, surface degradation, signs of micro-fracturing—all to confirm that when you take one of our tools to a job site, it has already survived a lifetime of abuse before it even gets in your hands.

Where the Rubber Meets the Road: A Demolition Story

All this science means nothing if it doesn't perform in the real world. I remember one project in particular—a crew was tasked with tearing down an old, overbuilt industrial facility. They were facing walls of 50cm-thick reinforced concrete, the kind of stuff that eats lesser tools for breakfast. The foreman told me they’d budgeted for a high attrition rate on their chisels, expecting to swap them out every couple of hours. He took a chance on ours.

At the end of the first day, his crew came back with the same set of chisels they started with. After eight hours of continuous, grueling work, the tips were barely worn. They reported that the demolition was going 40% faster than they'd projected, not just because the chisels cut faster, but because they weren't wasting time on constant change-outs and trips back to the tool crib. That's what this is all about. It's not about passing a lab test; it's about giving professionals a tool that works as hard as they do, a tool they can trust when the job is at its toughest.

Forging the Future: What’s Next in Chisel Tech?

We're incredibly proud of the tools we forge today, but our metallurgists and engineers are never satisfied. The pursuit of the 'perfect' tool is a journey, not a destination. We're constantly exploring the cutting edge of material science, looking for the next breakthrough that will redefine what a demolition chisel can do. We're experimenting with advanced nano-coatings that could one day create a cutting surface with unprecedented hardness and wear resistance. We're delving into the world of composite materials and smart alloys, dreaming of tools that can adapt to different materials in real-time or even signal when they are approaching their fatigue limit.

This isn't science fiction. This is the future of tool manufacturing. By staying at the forefront of research, we’re not just making better tools for today; we're building the foundation for the tools of tomorrow. Our commitment is to you—the professional in the field—to keep innovating, to keep pushing the boundaries, and to ensure that the tool in your hand is always the best it can possibly be.