What Procurement Fears Most

- Labels fall off after long storage, breaking the trail between raw stock and finished goods

- Emergency rush orders tempt operators to swap materials off the record

- Customer or third-party audits stall because traceability evidence lives in silos

- Disconnected systems leave sales, planning, and warehouse teams with conflicting data

How Zhonghuan De-Risks It

- Daily 5S audits plus QR patrols keep every batch readable and accounted for

- Kingdee Cloud Xingchen ERP enforces material issuance checks and flags unsanctioned substitutions

- End-to-end QR genealogy serves audit-ready evidence in under three seconds

- Shared data backbone keeps sales, planning, and warehouse aligned on one source of truth

The Soul of a Tool

A rotary hammer bit is never just steel and carbide—it is a promise. A promise of a precise opening, a job site that runs on schedule, a contractor who can sign off with confidence. In what many Chinese buyers call a “mixed pond of dragons and snakes”, we know that promise lives long before the forging furnace ever lights up.

For procurement leaders, supplier selection is a chess match between risk and certainty. We hide our answer inside the warehouse: a yellow line on the floor, a QR code on a pallet, a dataset that stays intact from day one. Quality is not discovered at the end of the line—it is engineered into every motion from the very start.

5S: The Philosophy of Order

“A tidy room can brighten a humble abode.” The proverb becomes a daily management rule on our shop floor.

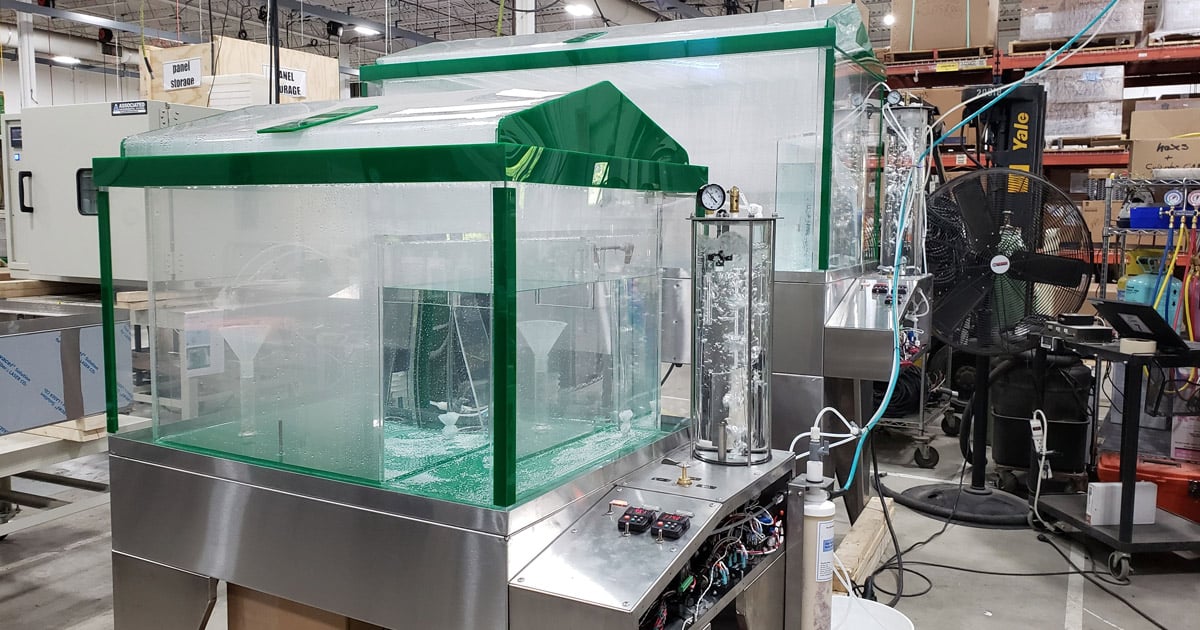

Step into our high-bay warehouse and you feel it immediately—the discipline that turns small gestures into enterprise-level trust. 5S is not a poster on the wall; it is a rhythm that converts hidden variability into visible standards, and it trains every operator to become a steward of certainty.

- Seiri (Sort): Every 40Cr steel bar and YG8 insert is registered in the system, and non-essential items are purged the same day to eliminate mix-up risk.

- Seiton (Set in order): Shelf coding works like an industrial library index, guiding operators to the right material in minutes—not hours.

- Seiso (Shine): Scheduled patrols prevent corrosion, dust, and contamination so raw materials stay in peak condition.

- Seiketsu (Standardize): Visual boards and video SOPs capture experience and make it repeatable across every shift.

- Shitsuke (Sustain): From warehouse chief to forklift driver, everyone signs off on daily 5S checkpoints—discipline becomes muscle memory.

The Digital Twin: Kingdee Cloud Xingchen ERP

Order in the physical world has a digital twin living inside our Kingdee Cloud Xingchen ERP. It is the glass window that connects warehouse, production, and sales so traceability is more than a slogan—it is code.

- Unique QR issuance: Every batch of carbide tips from our certified partner receives a system-generated identity code as soon as it lands and is affixed to the pallet.

- PDA-driven receiving: Supplier, PO number, arrival date, batch code, weight, and shelf position are captured in a single scanning action.

- Shared inventory heartbeat: The moment the entry is saved, sales, planning, and management dashboards update in real time.

This is not data for data’s sake; it is data for accountability. Every scan is an affirmation that information stays intact and responsibility stays visible.

Traceability in Action

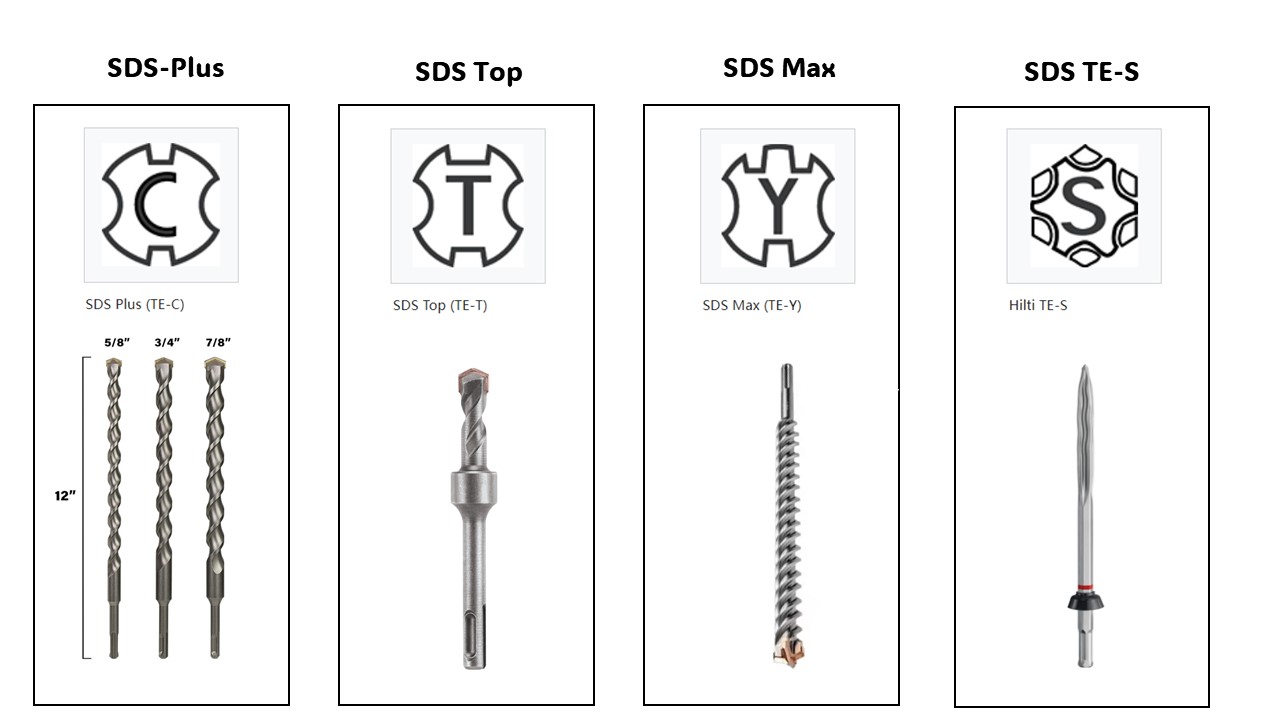

Imagine placing a 5,000-piece SDS-Plus order. Once the work order is released, the ERP locks in batch ZZ202511 and its location. Guided by PDA, the operator walks to Shelf A-03-Level-4, scans the QR code, and confirms the pick. From that moment on, every drill bit on the line is digitally bonded to that specific steel and carbide batch.

Years later, if a single bit on a remote job site raises a question, scanning its production code reveals the supplier, inbound date, heat-treatment furnace, and QC report. It is an audit-ready chain of evidence that delivers facts—not apologies.

Why Procurement Leaders Care

Whether you oversee procurement for international projects or run the sourcing desk for a major contractor, what you really buy is risk mitigation. Our system decomposes hidden risk into measurable controls, delivering certainty you can present to your board—or your client.

- One-visit audits: warehouse discipline and digital records align, ready for surprise inspections.

- Non-negotiable allocations: ERP-enforced picks stop unsanctioned substitutions before they happen.

- Rapid service response: three-second trace-back means customer investigations no longer drag on for weeks.

- Authority in search: structured data and real case signals tell Google you are dealing with a vetted expert supplier.

Conclusion: Certainty Delivered

In a market flooded with low-cost uncertainties, we choose to build trust from the ground up. Quality is not the lucky by-product of final inspection—it is the warehouse floor, the PDA screen, and the work order logic acting in unison. Partner with Zhonghuan Tools and you take delivery not just of a drill bit, but of a traceability spine woven from 5S discipline and ERP rigor.

That spine ensures every pick, every report, every audit has proof on demand. You are no longer buying possibility—you are securing verifiable certainty.

.jpg)