The Golden Formula (RPM vs SFM)

Drilling speed isn't a guess; it's physics. The goal is to keep the cutting edge moving at the optimal speed for the material hardness.

RPM = (SFM × 3.82) / Diameter

- RPM: Revolutions Per Minute (Speed setting)

- SFM: Surface Feet per Minute (Material Hardness Factor)

- Diameter: Drill bit size in inches

Surface Speed (SFM) by Material

Before using the chart, know your material. Harder metals require slower speeds (Lower SFM).

- Stainless Steel (304/316): 40-60 SFM (Slow & Heavy Pressure)

- Mild Steel (1018/A36): 80-110 SFM (Standard Speed)

- Brass / Bronze: 150-300 SFM (Fast & Light Pressure)

- Aluminum: 250+ SFM (Very Fast + Lubrication)

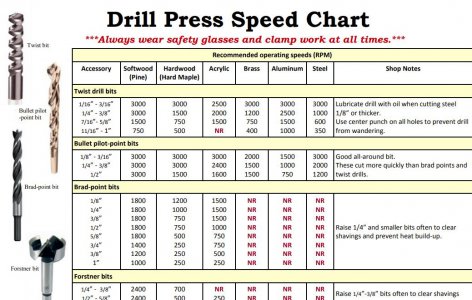

Master RPM Chart (HSS Bits)

Use this reference table for standard HSS drill bits. If using Cobalt (M35/M42), you can run ~10% faster. If using Carbide, you can run 2-3x faster.

| Size (mm) | Size (inch) | Stainless (50 SFM) | Mild Steel (100 SFM) | Aluminum (300 SFM) |

|---|---|---|---|---|

| 1.6mm | 1/16" | 3000 | 6000 | 9000+ |

| 3mm | 1/8" | 1500 | 3000 | 9000 |

| 5mm | 3/16" | 1000 | 2000 | 6000 |

| 6mm | 1/4" | 750 | 1100 | 4500 |

| 8mm | 5/16" | 600 | 1000 | 3600 |

| 10mm | 3/8" | 500 | 800 | 3000 |

| 13mm | 1/2" | 380 | 760 | 2200 |

| 19mm | 3/4" | 250 | 500 | 1500 |

| 25mm | 1" | 190 | 380 | 1100 |

Troubleshooting Squeaks and Smoke

Sound Check

- Squealing/Screaming: Speed is too high. You are rubbing, not cutting. Slow down and press harder.

- Chattering/Rumbling: Speed is too low or not enough rigid support.

- Crunching: Feed rate is too high (pushing too hard) or bit is chipped.

Visual Check

- Blue Chips: Good for mild steel (heat leaving with chip). Bad for stainless.

- Smoke: Lack of coolant. Add oil immediately.

- Powder instead of Chips: Dull bit or scraping (rubbing). Sharpen the bit or apply more pressure.