The Golden Formula

Don't guess. The math is simple. To find the perfect drill bit size for any cutting tap:

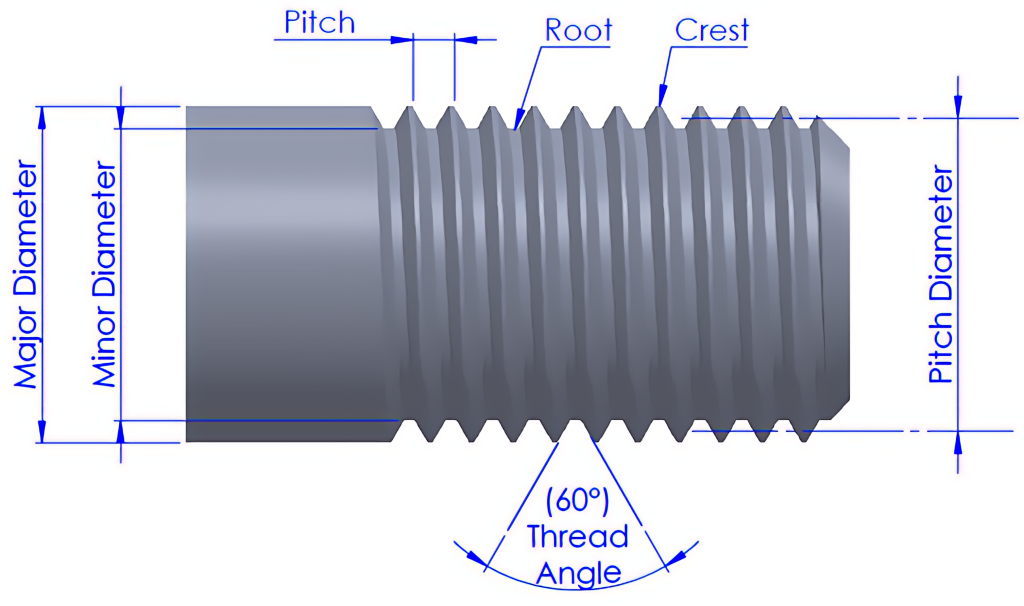

Drill Bit Size = Tap Diameter - Thread Pitch

Example (Metric): M10 x 1.5 Pitch

10mm - 1.5mm = 8.5mm Drill Bit.

Example (Imperial): 1/4"-20 (20 threads per inch)

Pitch = 1/20 = 0.050".

0.250" - 0.050" = 0.200" (#7 Bit).

Metric Tap Drill Chart (Standard Coarse)

| Tap Size | Pitch (mm) | 75% Thread Drill (mm) | Closest ANSI Bit |

|---|---|---|---|

| M3 | 0.5 | 2.5 mm | #39 |

| M4 | 0.7 | 3.3 mm | #30 |

| M5 | 0.8 | 4.2 mm | #19 |

| M6 | 1.0 | 5.0 mm | #9 |

| M8 | 1.25 | 6.8 mm | H |

| M10 | 1.5 | 8.5 mm | Q |

| M12 | 1.75 | 10.2 mm | 13/32" |

Imperial (SAE) Tap Drill Chart

| Tap Size | TPI | Drill Size | Decimal Equiv |

|---|---|---|---|

| 6-32 | 32 | #36 | 0.1065" |

| 8-32 | 32 | #29 | 0.1360" |

| 10-24 | 24 | #25 | 0.1495" |

| 10-32 | 32 | #21 | 0.1590" |

| 1/4"-20 | 20 | #7 | 0.2010" |

| 5/16"-18 | 18 | F | 0.2570" |

| 3/8"-16 | 16 | 5/16" | 0.3125" |

| 1/2"-13 | 13 | 27/64" | 0.4219" |

Forming Taps vs. Cutting Taps

Warning: The charts above are for Cutting Taps (which make chips). If you are using Forming Taps (Roll Taps) that displace metal without chips, you must use a larger drill bit.

Formula for Forming Taps:

Drill Size = Tap Dia - (0.5 x Pitch)