Chipping: Root Causes & Field Solutions

Tip chipping is the most common field failure, often striking at critical moments and severely impacting project schedules. Through systematic analysis of chipping mechanisms, we can develop effective prevention and response strategies.

Primary Chipping Causes

- Impact Overload: Forcing through rebar or hard aggregate, instantaneous impact exceeds tip limits

- Thermal Stress: Continuous operation causes overheating, thermal cycling creates micro‑cracks

- Material Mismatch: Using standard grades on ultra‑high‑strength concrete

- Operator Error: Excessive start RPM, side loading, angled drilling

- Equipment Issues: Insufficient hammer power, abnormal impact frequency, loose chuck

Chipping Case Study Analysis

- Case 1: C50 concrete with YG8C tip, chipped in 5 minutes → Solved with YG11C upgrade

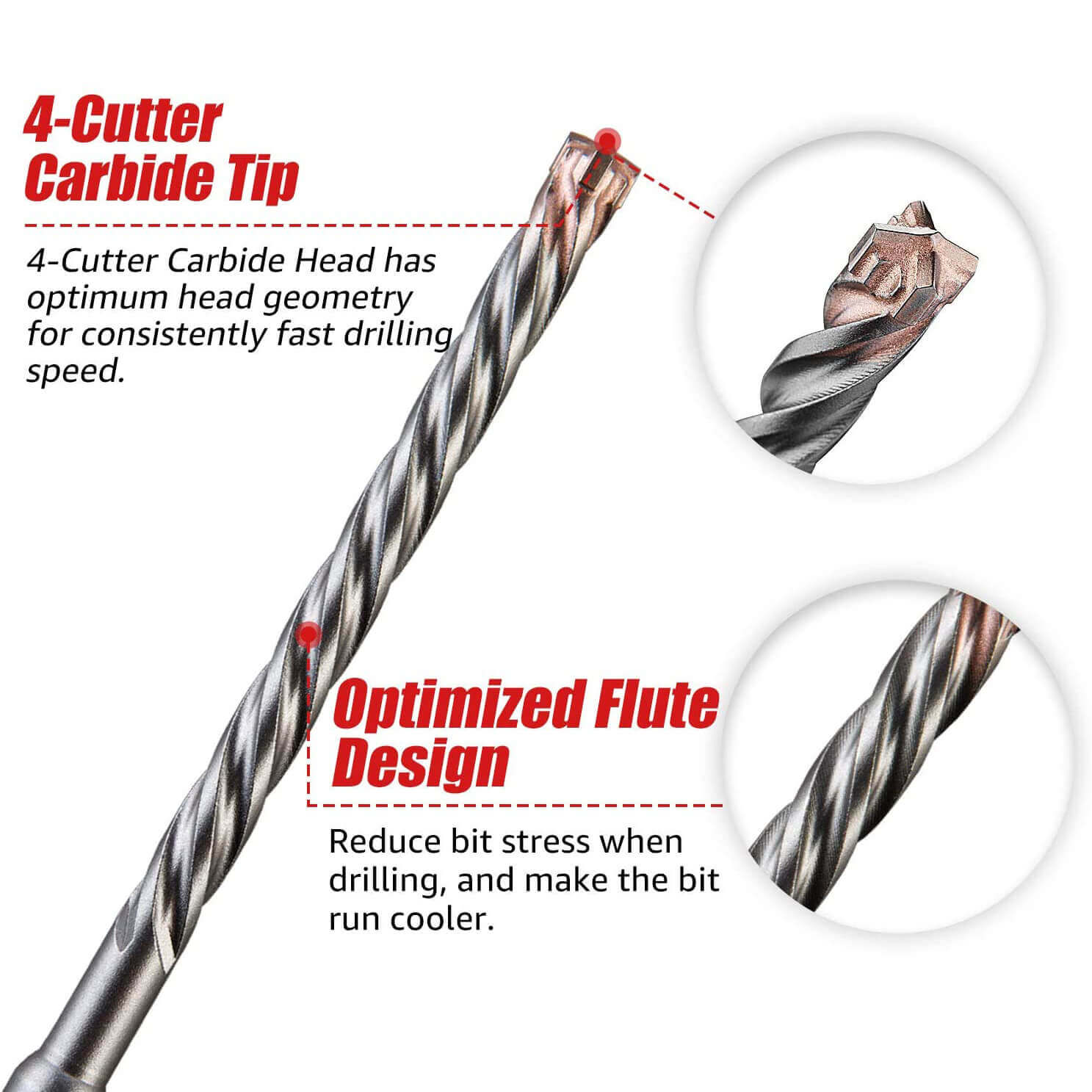

- Case 2: Dense 32mm rebar, 2‑cutter frequent chipping → Resolved with cross‑head geometry

- Case 3: 2‑hour continuous drilling, thermal chipping → Fixed with cooling intervals

Chipping Prevention Strategy

- Material Matching: C40+ concrete requires YG11C or higher hardness grades

- Parameter Optimization: Reduce start RPM to 300‑500 RPM

- Thermal Management: 30‑second cooling break every 10‑15 holes

- Rebar Detection: Use detector to map and adjust hole layout

Drift: Guidance Engineering & Control

Hole drift compromises installation precision and can create structural safety risks. Understanding drift formation mechanisms is key to effective solutions.

Drift Formation Mechanisms

- Start Deflection: Uneven surfaces cause bit "skating" away from target

- Rebar Deflection: Bit deflects toward path of least resistance when hitting rebar

- Material Inconsistency: Density variations cause drift toward softer zones

- Equipment Factors: Tool weight imbalance, operator fatigue affecting stance

Drift Correction Techniques

- Pilot Hole Method: 3‑5mm pilot + progressive diameter increase

- Cross‑Head Guidance: Use cross‑head bits for enhanced tracking

- Staged Drilling: Check alignment every 50mm, correct as needed

- Equipment Stabilization: Support stands or guidance fixtures

Precision Control Standards

- General Construction: Deviation ≤ 5mm/100mm depth

- Precision Installation: Deviation ≤ 2mm/100mm depth

- Chemical Anchors: Deviation ≤ 1mm/100mm depth

Jam: Evacuation & Safe Release

Bit jams are the most frustrating field problems. Improper handling can lead to bit breakage, equipment damage, or injury. Mastering correct release techniques is critical.

Jam Cause Analysis

- Dust Accumulation: Inadequate chip clearing in deep holes, dust caking and seizing

- Rebar Entrapment: Bit wedged in rebar gaps, unable to advance or retract

- Hole Collapse: Loose concrete or void areas causing wall collapse around bit

- Thermal Expansion: Overheating causes bit expansion, binding with hole walls

Safe Release Procedure

- Immediate Stop: Cut power to prevent further damage

- Reverse Attempt: If supported, low‑speed reverse for 10‑15 seconds

- Cooling Wait: Allow 5‑10 minutes for thermal contraction

- Vibration Release: Light tapping around bit to loosen debris

- Local Chiseling: Use small chisel to clear material around hole mouth

- Professional Extraction: Use specialized broken tap extractors if needed

Jam Prevention Operating Points

- Peck Rhythm: Retract for chip clearing every 20‑30mm penetration

- Cooling Intervals: Stop for cooling after 5‑10 continuous holes

- Parameter Adjustment: Reduce feed rate 30‑50% for deep hole operations

- Bit Inspection: Check for wear and deformation each shift

Failure Prevention System

Equipment Maintenance Prevention

- Daily Checks: Chuck tightness, impact mechanism, power cord condition

- Regular Service: Chuck lubrication, vent cleaning, wear part replacement

- Calibration Testing: Impact energy testing, RPM calibration, torque verification

Bit Management Prevention

- Classified Storage: Organize by material, diameter, geometry

- Wear Monitoring: Maintain bit usage logs, timely replacement

- Quality Control: Verify hardness and geometric precision at purchase

Operational Standards Prevention

- Personnel Training: Standard procedures, failure recognition, emergency response

- Process Optimization: Develop parameter tables for different materials

- Site Management: Tool inspections, operation logs, experience sharing