Not All Drills Are Created Equal

Walk onto any serious job site, and you'll see two letters everywhere: SDS. It stands for 'Special Direct System,' but what it really means is 'power.' It's a revolutionary system that allows for lightning-fast bit changes and a far more efficient transfer of hammer energy from the drill to the bit. It's the standard for a reason. But within that standard, there's a crucial choice to be made, a choice that separates the pros from the amateurs: SDS-Plus or SDS-Max?

Think of it like choosing between a scalpel and a sledgehammer. Both are tools designed for impact, but you wouldn't use a sledgehammer for delicate surgery, and you wouldn't use a scalpel to break down a wall. Choosing the right system for the job isn't just about power; it's about efficiency, precision, and using the right tool for the right reason.

The Scalpel: Meet the SDS-Plus

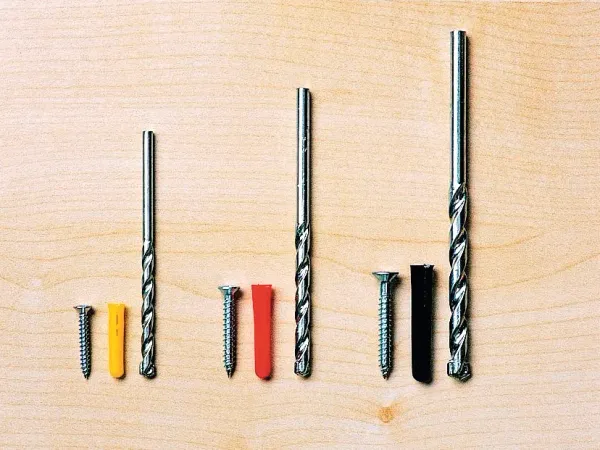

The SDS-Plus is the finesse player of the rotary hammer world. It's lighter, it's more agile, and it's what you'll reach for on the vast majority of jobs. With its 10mm shank, it's designed for drilling holes for anchors, running conduit, and light-duty chipping and scaling. Think of it as the tool for precision work. When you need to drill a clean, accurate hole in brick or standard concrete without causing a lot of damage to the surrounding area, the SDS-Plus is your go-to.

Its key advantage is its versatility and ease of use. The drills are lighter, which means less operator fatigue over a long day. The bits are more affordable and available in a massive range of sizes. For any job that requires drilling holes up to about an inch in diameter, or for any task that requires you to work with a degree of surgical precision, the SDS-Plus is the undisputed champion.

The Sledgehammer: Meet the SDS-Max

When precision takes a back seat to pure, unadulterated power, you call in the SDS-Max. This is the big brother, the heavyweight champion of demolition. With its beefy 18mm shank, the SDS-Max system is built for one thing: maximum destruction. It's designed to handle the massive torque and impact energy of the largest rotary and demolition hammers on the market.

This is the system you use when you're drilling large-diameter holes for rebar dowels, running pipe through thick concrete walls, or turning a slab of concrete into a pile of rubble. The tools are heavier, the bits are bigger, and the impact is ferocious. You don't choose an SDS-Max for a delicate job. You choose it when you have a serious amount of material to move, and you need to do it as quickly and violently as possible. It's the sledgehammer to the SDS-Plus's scalpel.

Head-to-Head: The Nitty Gritty

| Feature | SDS-Plus | SDS-Max |

|---|---|---|

| Shank Diameter | 10mm | 18mm |

| Insertion Length | 40mm | 90mm |

| Drilling Diameter Range | 6-25mm | 12-80mm |

| Suitable Hammer Power | 500-1200W | 1200W+ |

| Maximum Drilling Depth | 300mm | 1000mm+ |

| Weight | Lightweight | Heavy-duty |

| Price Range | Economic | Professional |

When to Reach for Which: A Pro’s Playbook

So, how do you choose? It comes down to the job at hand. Are you a residential contractor doing a kitchen remodel, hanging cabinets, and drilling for plumbing? An SDS-Plus is your workhorse. It’s light enough to use all day, and precise enough for finished spaces. Are you an electrician running conduit in a commercial building? Again, SDS-Plus is your best bet for speed and efficiency.

But if you're on a heavy industrial site, breaking up a machine foundation, or on a major demolition job, bringing an SDS-Plus is like bringing a knife to a gunfight. This is SDS-Max territory. When the job is measured in tons of concrete, not in the number of holes, you need the raw, unapologetic power that only an SDS-Max can deliver. A good rule of thumb: if the hole is bigger than your thumb, it's probably a job for an SDS-Max.

Making the Call: A Quick Checklist

Still on the fence? Ask yourself these three simple questions:

- What's the biggest hole I need to drill? If the answer is consistently over an inch, you need to be looking at an SDS-Max.

- How much of my day is spent drilling vs. chipping? If you're doing more heavy demolition than drilling, the SDS-Max is your tool.

- How important is portability? If you're moving around a lot, working in tight spaces, or drilling overhead, the lighter weight of an SDS-Plus system is a massive advantage.

The Right Tool for the Right Reason

At the end of the day, both SDS-Plus and SDS-Max are incredible systems. The key is to be a craftsman, not just an operator. A craftsman understands their tools intimately and knows which one to pick for the task at hand. Most professionals will end up with both in their toolkit, because they know that having the right tool is the fastest way to a job well done. Choose the tool that fits the job, and you'll work faster, safer, and with a lot more confidence.