The Reality Check: We've Seen the Complaints

We've seen the threads on Reddit. We've seen the $15 power tool kits on TikTok. And honestly? We understand the frustration.

When a tool fails mid-job, "Made in China" often gets the blame. But as an ISO-certified OEM manufacturer for professional brands, we need to talk about the massive gap between Consumer Disposable and Industrial Professional.

This isn't just an article. This is a brand declaration. We're not here to defend cheap tools. We're here to explain why they fail—and why industrial-grade tools don't.

The 'Mystery Meat' of Metallurgy: Steel Is Not Just Steel

The Reddit Complaint: "The shank snapped like a twig after three holes."

The Manufacturer's Reality:

In the world of SDS drill bits, steel is not just steel.

The "TikTok grade" tools often use recycled carbon steel or standard A3 steel to cut costs. It looks shiny when new, but it lacks the fatigue resistance needed for rotary hammering.

At Zhonghuan Tools, we strictly use 40Cr structural steel for the body and premium YG8C Tungsten Carbide for the tip.

- Why it matters: 40Cr allows for heat treatment that balances hardness (to transmit energy) with toughness (to absorb shock). Cheap steel can only be hard (brittle) or soft (bends). It cannot be both.

- The Cost Reality: 40Cr costs 2-3x more than A3 steel. Budget factories skip it to hit that $5 price point. We don't.

- The Performance Gap: A3 steel shanks fail at 15-30 holes in C30 concrete. 40Cr shanks consistently deliver 200-400 holes before replacement.

Material Composition Comparison

| Component | TikTok/Dropshipper Grade | Zhonghuan Industrial OEM |

|---|---|---|

| Shank Material | Recycled Carbon Steel / A3 | 40Cr Structural Steel |

| Carbide Grade | YG6 or lower (basic) | YG8C / YG11C (premium) |

| Cobalt Content | 0-3% (minimal) | 5-8% (M35/M42 in HSS variants) |

| Hardness (HRC) | 58-62 (inconsistent) | 64-68 (premium, verified) |

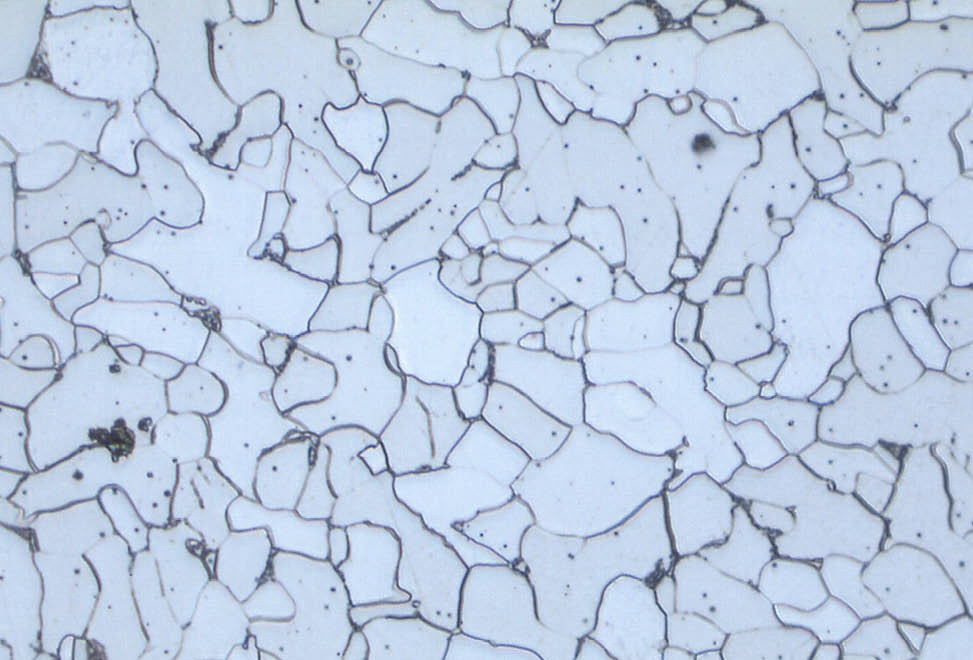

| Grain Structure | Coarse, irregular | Fine, uniform (controlled) |

| Bonding Method | Weak brazing, prone to delamination | Strong brazed/sintered, tested |

The Alchemy of Heat Treatment: The Invisible 50%

The Reddit Complaint: "The tip melted/fell off."

The Manufacturer's Reality:

You can't see heat treatment, but it accounts for 50% of a tool's cost and 90% of its durability.

Budget factories skip stages. They heat it up and cool it down—fast. That's it.

We follow a proprietary multi-stage quenching process (Salt Bath / High-Frequency Induction).

- The Secret: We create a "Hardness Gradient." The tip must be extremely hard to pulverize concrete, while the shank must be flexible enough to withstand the SDS chuck's torque without snapping.

- The Process: This takes hours, not minutes. That is why you don't find our quality in a $5 bargain bin.

- The Science: Proper heat treatment transforms the steel's microstructure. We control martensitic transformation, tempering cycles, and cooling rates to achieve the perfect balance.

Heat Treatment Stages: Budget vs Industrial

| Stage | Budget Factory | Zhonghuan Industrial Process |

|---|---|---|

| Preheating | Skipped or minimal | Controlled ramp-up to 400°C |

| Austenitizing | Single temperature, fast | Precise temperature control (850-880°C) |

| Quenching | Water/oil, fast cool | Salt Bath or High-Frequency Induction |

| Tempering | Single cycle, inconsistent | Multi-stage (2-3 cycles, 200-600°C) |

| Hardness Testing | None or random | Every batch, HRC verification |

| Time Investment | 15-30 minutes | 3-6 hours per batch |

Why We Talk About PPAP and Traceability

The Reddit Complaint: "Is this a real factory or just a dropshipper?"

The Manufacturer's Reality:

Real industrial manufacturing runs on data, not viral videos.

When global brands buy from us, they demand PPAP (Production Part Approval Process) and Incoming Quality Control.

- Traceability: If a Zhonghuan drill bit fails 2 years from now, our ERP system (linked to the batch number) can trace back to the specific furnace temperature on the day it was made and the specific batch of steel raw material.

- Material Certificates: Every batch of 40Cr steel comes with material certificates. Every YG8C carbide tip is traceable to its production lot.

- Quality Records: We maintain records of hardness tests, dimensional checks, and performance validation for every production batch.

Scammers don't have ERP systems. They don't have ISO 9001 certifications. They don't offer traceability. We do.

What Real OEM Manufacturing Looks Like

- ISO 9001 Certification: Quality management system audited annually

- PPAP Documentation: Production Part Approval Process for every new product

- ERP System: Batch-level traceability from raw material to finished product

- Material Certificates: Every steel batch, every carbide lot documented

- Quality Control Labs: In-house hardness testing, metallographic analysis, dimensional verification

- Production Records: Furnace logs, heat treatment cycles, inspection reports

Carbide Grade Secrets: YG6 vs YG8C vs YG11C

The Reddit Complaint: "The tip chipped on the first rebar hit."

The Manufacturer's Reality:

Not all tungsten carbide is created equal. The grade determines everything.

- YG6 (Budget Grade): Basic carbide, suitable for soft materials. Chips easily on rebar or hard aggregate. Used in $5-10 drill bits.

- YG8C (Industrial Standard): Our standard grade. 8% cobalt content, fine grain structure. Handles C30-C40 concrete and occasional rebar hits. Used in professional tools.

- YG11C (Premium Grade): 11% cobalt, ultra-fine grain. For C50+ concrete, dense rebar, extreme conditions. Used in our premium product lines.

The difference isn't just in the numbers—it's in the grain structure, cobalt distribution, and sintering process. Budget factories use coarse-grained YG6 because it's cheaper to produce. We invest in fine-grained YG8C/YG11C because it lasts 10-20x longer.

Carbide Performance Comparison

| Grade | Typical Use | Rebar Impact | Concrete Grade | Holes per Bit (C30) |

|---|---|---|---|---|

| YG6 | Budget/TikTok tools | Fails frequently | C20-C30 only | 15-30 |

| YG8C | Industrial standard | Handles well | C30-C40 | 200-400 |

| YG11C | Premium/extreme duty | Excellent | C40-C60+ | 400-800+ |

Geometry Matters: Why Flute Design Determines Life

The Reddit Complaint: "The bit got stuck and overheated."

The Manufacturer's Reality:

Drill bit geometry isn't just about looks—it's about chip evacuation, heat dissipation, and cutting efficiency.

- Flute Design: Budget bits have inconsistent flute spacing and poor helix angles. Chips get trapped, causing overheating and jamming.

- Our Approach: CNC precision grinding ensures consistent geometry. Optimized flute design maximizes chip evacuation, reducing heat buildup by 40-60%.

- The Impact: Proper geometry allows deeper drilling (150-200mm vs 80-100mm) and faster speeds without overheating.

This is why industrial bits can drill continuously while budget bits require constant breaks for cooling.

The OEM Difference: Data, Not Viral Videos

Here's what separates real OEM manufacturers from TikTok dropshippers:

- We Have Labs: Metallographic analysis, hardness testing, performance validation—all in-house

- We Have Data: Every production batch is logged, tested, and traceable

- We Have Standards: ISO 9001, PPAP, material certifications—not just marketing claims

- We Have Accountability: If something fails, we can trace it back to the exact cause

Dropshippers have viral videos. We have engineering data.

Real Manufacturing vs. Dropshipping

| Aspect | TikTok Dropshipper | Zhonghuan OEM Factory |

|---|---|---|

| Factory Ownership | No factory, uses third-party | Own manufacturing facility |

| Quality Control | None or minimal | Full QC lab, batch testing |

| Material Traceability | None | Full ERP traceability |

| Certifications | None | ISO 9001, CE, material certs |

| Technical Support | None | Engineering team, field support |

| Customization | No | Yes, OEM/ODM services |

| Warranty | None or void | Full warranty, batch support |

We Are Not for Everyone: Industrial Grade vs Consumer Disposable

If you are drilling one hole to hang a picture frame, a generic online tool might suffice.

But if your livelihood depends on your tools, or if you are a distributor staking your reputation on product quality, you are looking for an OEM partner, not a dropshipper.

Zhonghuan Tools stands on the side of Industrial Grade. We don't sell "cheap." We sell "cost-effective engineering."

The Bottom Line

- Consumer Disposable: $5-15, breaks after 15-30 holes, no warranty, no traceability, perfect for one-time DIY projects

- Industrial Professional: $20-50, lasts 200-400+ holes, full warranty, complete traceability, designed for professionals who depend on their tools

The gap isn't about geography—it's about standards. We're not competing with TikTok dropshippers. We're serving professional brands and serious contractors who understand that quality engineering costs more upfront but saves money long-term.

When a drill bit breaks mid-job, everything stops. Industrial-grade bits keep you working. That's the difference.