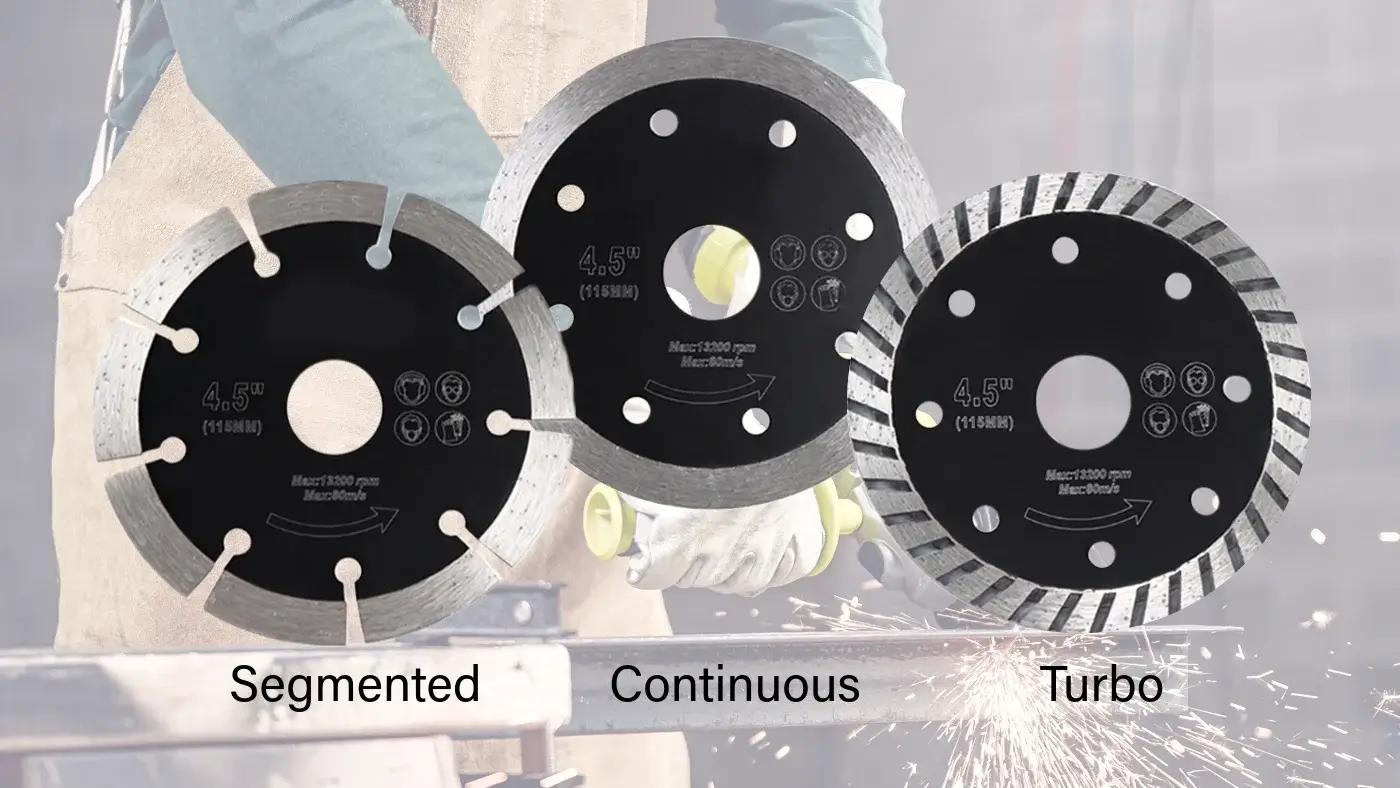

Diamond Blade Rim Types Comparison

Choosing the wrong rim type is the #1 reason for slow cutting or ruined materials. Here is the cheat sheet:

| Rim Type | Cut Speed | Finish Quality | Best For | Wet/Dry |

|---|---|---|---|---|

| Segmented | Fastest | Rough | Concrete, Asphalt, Brick | Both |

| Turbo | Fast | Medium/Smooth | Granite, Hard Stone, General | Both |

| Continuous | Slow | Ultra Smooth | Ceramic Tile, Porcelain, Glass | Wet Only |

Segmented Rim: The Rough Cut King

Recognizable by: Distinct gaps (gullets) between diamond segments.

These gaps serve two purposes: cooling the blade and ejecting dust. This makes Segmented blades the most aggressive option. They can survive the high heat of dry cutting concrete.

- Ideal for: Reinforced Concrete, Old Concrete, Asphalt, Pavers.

- Warning: Will cause chipping on tile or glass.

Turbo Rim: Speed and Finish

Recognizable by: A continuous rim with serrated "gear-like" edges.

The serrated edge reduces friction (like segments) but maintains continuous contact (for smoothness). The "Turbo" design ejects debris faster than a flat rim.

- Ideal for: Granite slabs, Marble, Hard Brick, General Masonry.

- Pro Tip: Most general-purpose 4.5" angle grinder blades are Turbo rims.

Continuous Rim: Zero Chipping

Recognizable by: A completely smooth, flat diamond edge.

Without gaps to dissipate heat, these blades MUST be used with water. The continuous contact ensures the cutting edge does not hammer the material, preventing chips.

- Ideal for: Bathroom Tiles, Porcelain, Glass, Delicate Stone.