Nothing stops a job faster than a drill bit jamming violently or snapping off inside a deep hole. Here is how to handle the situation like a pro.

1. Why Drill Bits Jam (The 3 Culprits)

- Rebar Strike: In concrete, hitting a steel reinforcement bar will stop a 2-cutter bit instantly. The tip catches on the steel rib.

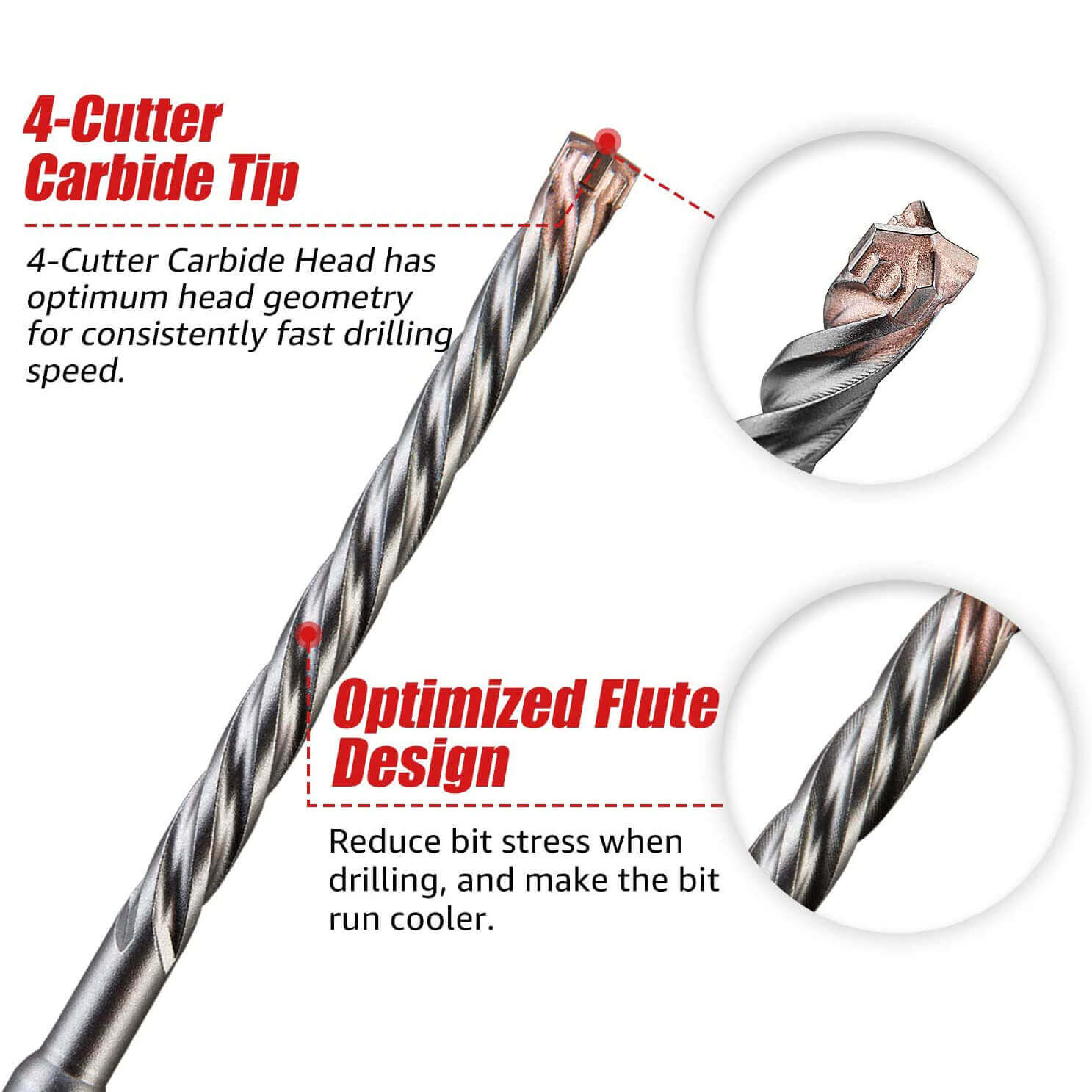

- Debris Packing: If you don't pull the bit out frequently to clear dust, the flute gets packed solid. The friction locks the bit in place.

- Binding (Angle Change): If you hold the drill crooked halfway through, the bit bends and binds against the straight walls of the hole.

2. The Safety Clutch: Your Best Friend

If your heavy rotary hammer suddenly makes a loud CLICK-CLICK-CLICK sound and the bit stops spinning, do not panic. This is the Safety Clutch.

It saved your wrist from breaking. Stop immediately. Put the drill in Reverse and gently back it out. Do NOT just pull the trigger harder.

3. Rescue Mission: Removing a Broken Bit

Scenario A: Sticking Out

Easy. Clamp locking pliers (Vice-Grips) perpendicular to the shank and turn counter-clockwise while pulling.

Scenario B: Flush or Deep

Hard. You can try a strong magnet (for loose bits) or needle-nose pliers. If it is jammed tight and deep, you often have to abandon the hole. Fill it with filler and drill a new hole 2 inches away.

4. Prevention: Pecking and Clearing

The #1 rule for deep holes is Pecking.

Drill 1 inch -> Pull out to clear dust -> Drill 1 inch -> Pull out.

This keeps the flute empty and the bit cool. If you try to drill 6 inches in one go, you are asking for a jam.