What is an MTC (and Why You Need It)

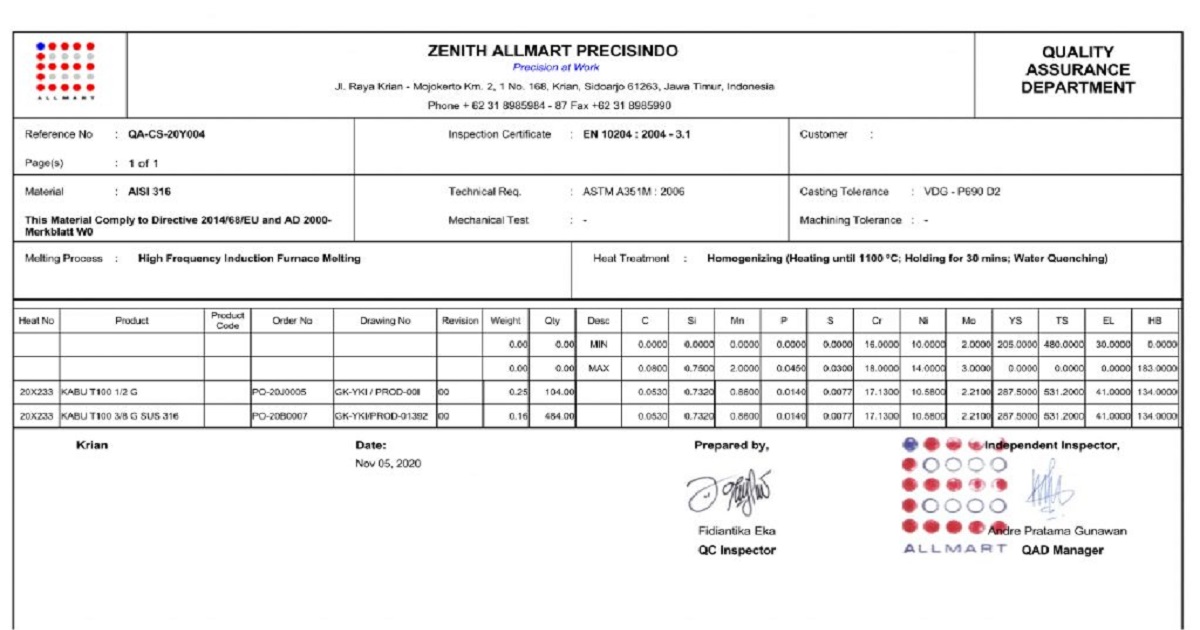

A Mill Test Certificate (MTC), often compliant with EN 10204 3.1, is the "Birth Certificate" of the steel used to make your tools.

If you are buying "M35 Cobalt Drill Bits" from a supplier, how do you know they actually contain 5% Cobalt? You ask for the MTC. If they can't provide it, or the Heat Number doesn't match the product, walk away.

Section 1: Chemical Composition

This is where you verify the alloy elements. For High Speed Steel (HSS), look for these key elements:

| Element | Symbol | Function |

|---|---|---|

| Tungsten | W | Primary hardness and wear resistance. (~6% in M2) |

| Molybdenum | Mo | Heat resistance and toughness. (~5% in M2/M35) |

| Chromium | Cr | Corrosion resistance and hardenability. (~4%) |

| Cobalt | Co | Red Hardness. Must be 4.8-5.0% for M35. |

Section 2: Mechanical Properties

Chemistry tells you what it is; Mechanical Properties tell you how it behaves.

- Hardness (HRC): The most critical metric for drill bits. M2 HSS should be HRC 63-65. M35 should be HRC 64-67. If the MTC shows HRC 55, it's garbage.

- Yield Strength: The force required to permanently bend the steel. Important for long SDS drill bits.

Red Flags: How to Spot a Fake MTC

Warning Signs:

- Photoshop Edits: Look for different fonts or pixelated text around the Heat Number.

- Missing Headers: A real MTC comes from a Steel Mill (e.g., Baosteel, Tiangong), not the drill bit factory.

- Generic Values: If the Carbon content is exactly "0.900%", it's fake. Real tests have variance (e.g., "0.893%").