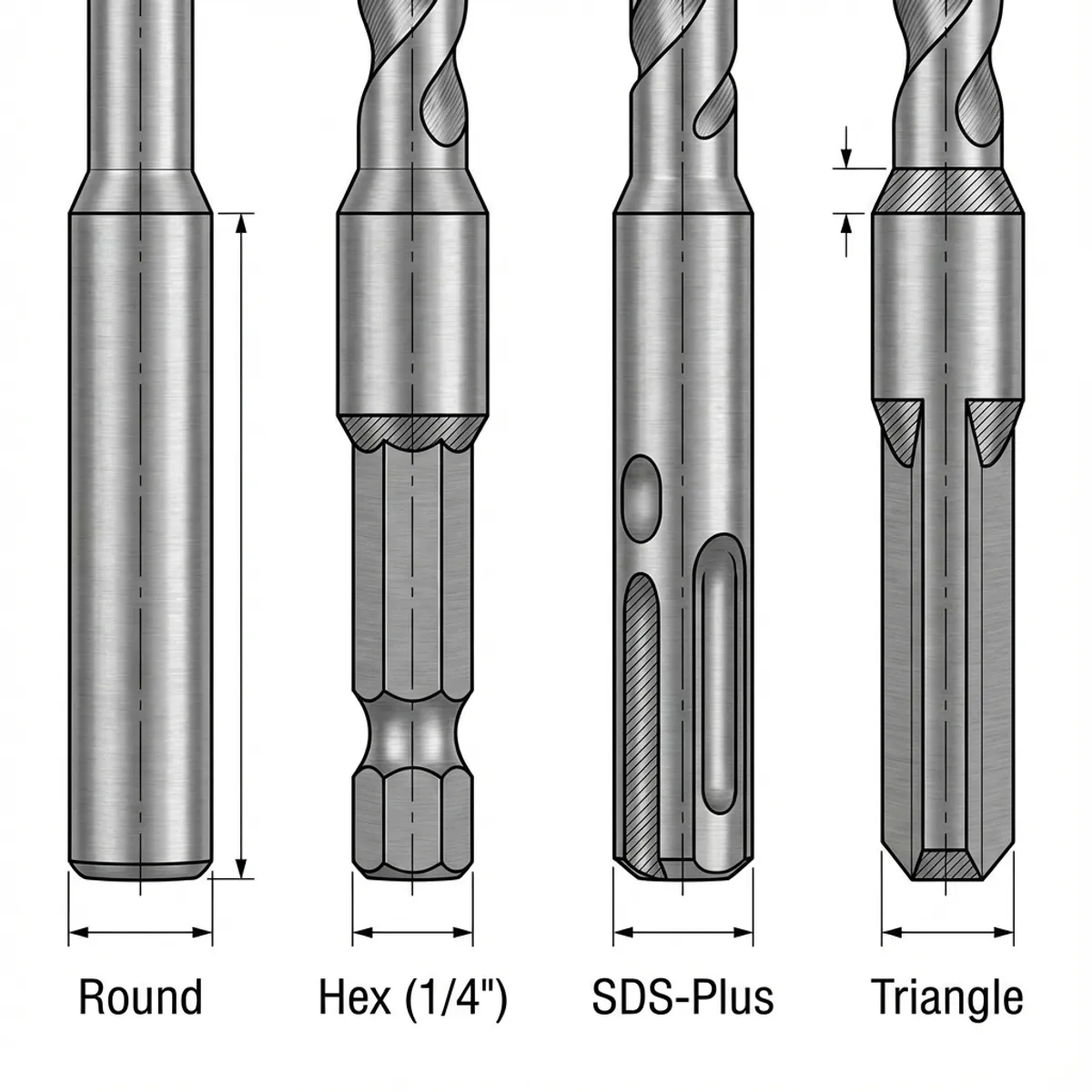

The "shank" is the end of the drill bit that goes into your power tool. If you buy the wrong shank, it won't fit, or worse, it will ruin your chuck.

1. Straight / Round Shank

The Classic. A smooth cylinder.

Fits: Standard 3-jaw Chucks (Corded and Cordless Drs).

Pros: Most accurate (perfectly centered).

Cons: Prone to spinning (slipping) inside the chuck under heavy load.

2. Hex Shank (1/4" Quick Change)

The Modern Standard. A six-sided hexagon.

Fits: Impact Drivers and Standard Drills.

Pros:

- No Slipping: The chuck jaws grip the flat sides positively.

- Quick Change: Fits into 1/4" hex impact drivers instantly.

3. SDS Shank (Slotted Drive System)

The Concrete Beater. Has grooves and slots on the side.

Fits: Rotary Hammers (Not standard drills).

The Mechanism: The bit is locked in by ball bearings but can slide back and forth like a piston. This transfers the massive hammering force directly to the tip without destroying the chuck.

4. Triangle / 3-Flat Shank

The Heavy Duty. A round shank with 3 flats ground onto it.

Fits: Standard 3-jaw Chucks.

Why? Used for large diameter bits (e.g., >10mm metal bits) to give the jaws a flat surface to grip, preventing slipping without needing a special Hex chuck.