Material Properties Compared

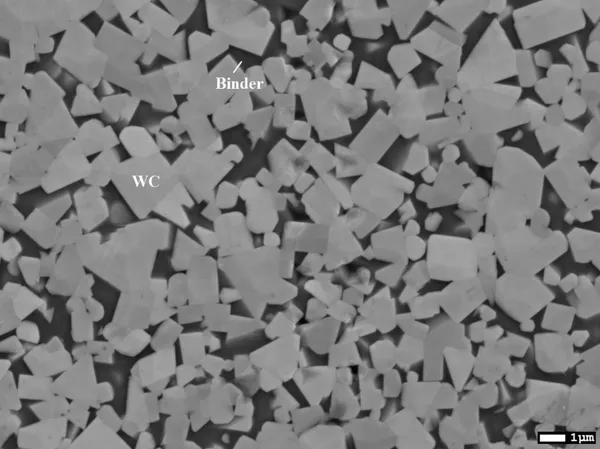

Understanding the fundamental differences between carbide (tungsten carbide) and HSS (high-speed steel) helps you make informed decisions.

Hardness

| Property | HSS | Carbide |

|---|

| Hardness (HRC) | 62-67 HRC | 89-93 HRA (≈74-78 HRC equivalent) |

| Wear Resistance | Good | Excellent (3-5x better) |

| Edge Retention | Moderate | Excellent |

Heat Resistance

| Property | HSS | Carbide |

|---|

| Max Working Temp | ~600°C (1112°F) | ~800°C (1472°F) |

| Hot Hardness | Drops above 500°C | Maintains to 700°C+ |

| Thermal Conductivity | Lower | Higher (better heat dissipation) |

Toughness & Brittleness

| Property | HSS | Carbide |

|---|

| Toughness | High—bends before breaking | Low—shatters under impact |

| Impact Resistance | Excellent | Poor |

| Flexibility | Can flex slightly | Rigid, no flex |

Cutting Speed

- Carbide: Can run 2-4x faster than HSS

- HSS: Lower speeds required to prevent overheating

- Result: Carbide offers dramatically higher productivity in production settings

Tool Life

- Carbide: 5-20x longer life in most materials

- HSS: Shorter life but can be resharpened easily

- Result: Carbide has lower cost-per-hole despite higher initial price

Hole Quality

- Carbide: Better finish, tighter tolerances, less burr

- HSS: Good finish, may require deburring

- Result: Carbide preferred for precision applications

Resharpening

- HSS: Easy to resharpen with standard grinders

- Carbide: Requires diamond wheels, specialized equipment

- Result: HSS more practical for field resharpening

Best Applications for Each

Choose HSS When:

- Materials: Mild steel, aluminum, wood, plastic, brass

- Setup: Hand-held drilling, flexible setups, potential for deflection

- Volume: Low to medium production, occasional use

- Budget: Limited budget, need to resharpen in-house

- Conditions: Interrupted cuts, impact possible, unstable workpiece

Choose Carbide When:

- Materials: Hardened steel, stainless steel, cast iron, composites, abrasives

- Setup: CNC machines, rigid fixturing, stable conditions

- Volume: High production, continuous operation

- Priority: Speed, consistency, minimal tool changes

- Conditions: Continuous cuts, no impact, proper coolant available

Material-Specific Recommendations

| Material | Recommended | Notes |

|---|

| Mild Steel | HSS or Carbide | HSS sufficient for most; carbide for volume |

| Stainless Steel | Cobalt HSS or Carbide | Work hardening favors carbide speed |

| Hardened Steel (>40 HRC) | Carbide only | HSS cannot cut effectively |

| Cast Iron | Carbide preferred | Abrasive, wears HSS quickly |

| Aluminum | HSS | Carbide often overkill; risk of welding |

| Wood | HSS | No benefit from carbide hardness |

| Concrete/Masonry | Carbide-tipped | Hammer drill with carbide tips required |

| Composites (CFRP) | Carbide | Abrasive fibers destroy HSS |

Cost & ROI Analysis

Initial Cost Comparison

- HSS: $1-10 per bit (depending on size/grade)

- Carbide: $5-50+ per bit (3-10x more expensive)

Cost-Per-Hole Analysis

Example: Drilling 1000 holes in mild steel:

| Factor | HSS M2 | Solid Carbide |

|---|

| Bit Cost | $5 | $25 |

| Holes per Bit | 200 | 1000 |

| Bits Needed | 5 | 1 |

| Tool Cost | $25 | $25 |

| Time per Hole | 15 sec | 5 sec |

| Total Drill Time | 4.2 hours | 1.4 hours |

| Labor Cost (@$30/hr) | $126 | $42 |

| Total Cost | $151 | $67 |

Result: Despite 5x higher bit cost, carbide saves 56% overall due to speed and longevity.

Break-Even Analysis

- For <50 holes: HSS is more economical

- For 50-200 holes: Depends on material and setup time value

- For >200 holes: Carbide typically wins on total cost

Quick Selection Guide

Decision Flowchart

- Is the material harder than 40 HRC? → Yes: Carbide required

- Is this high-volume production? → Yes: Consider carbide for speed

- Is the setup rigid and stable? → No: Use HSS (carbide may break)

- Do you need to resharpen in the field? → Yes: Use HSS

- Is cost the primary concern? → Yes for low volume: HSS; Yes for high volume: Carbide

Hybrid Solutions

- Carbide-tipped HSS: HSS body with carbide cutting edges—combines toughness with wear resistance

- Coated HSS: TiN, TiAlN coatings extend HSS life significantly at moderate cost

- Cobalt HSS (M35, M42): Better heat resistance than standard HSS, cheaper than carbide