Mistake 1: No Pilot Point or Center Punch

The Problem

Starting a hole without marking causes the bit to "walk" or wander across the surface, resulting in misplaced holes and potential surface damage.

The Solution

- For metal: Always use a center punch to create a small indent

- For wood: Use an awl or nail to mark the spot

- For large holes: Drill a small pilot hole first (1/8" or 3mm)

- Alternative: Use a split-point drill bit designed to self-center

Mistake 2: Wrong Speed for the Material

The Problem

Using the same speed for all materials leads to overheating (too fast) or poor cutting and bit damage (too slow).

The Solution

| Material | Speed | Notes |

|---|---|---|

| Softwood | High (2000-3000 RPM) | Fast is fine |

| Hardwood | Medium (1000-2000 RPM) | Slow down for oak, maple |

| Aluminum | High with lubricant | Use cutting fluid |

| Mild Steel | Low-Medium (500-1000 RPM) | Slower for larger bits |

| Stainless Steel | Low (300-500 RPM) | Constant speed, firm pressure |

| Concrete | Per hammer drill spec | Let the hammer do the work |

Rule of thumb: Larger bits and harder materials = slower speed

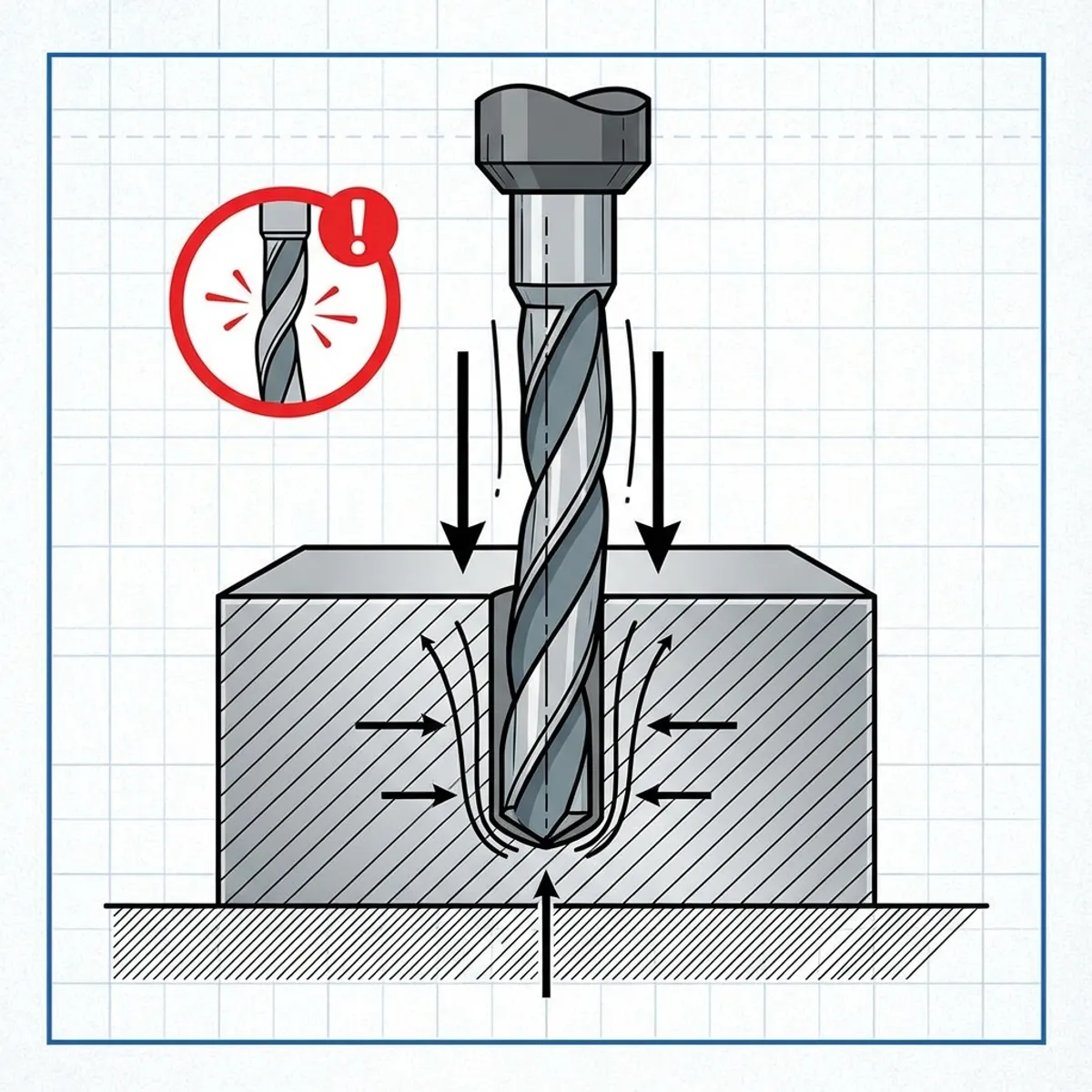

Mistake 3: Too Much Pressure

The Problem

Pushing too hard doesn't make drilling faster—it causes overheating, bit breakage, and poor hole quality.

The Solution

- Let the bit do the cutting—apply moderate, consistent pressure

- If the bit isn't advancing, it's likely dull or wrong speed—not lack of pressure

- For concrete: the hammer mechanism needs room to work; don't lean on it

- Watch for these signs of too much pressure: smoke, discoloration, squealing

Mistake 4: Using a Dull Bit

The Problem

A dull bit rubs instead of cuts, generating extreme heat and requiring 3-4x more force. This damages both the bit and workpiece.

The Solution

- Inspect before use: Look for rounded edges, chips, or discoloration

- Replace or sharpen: At the first sign of dullness

- For HSS: Resharpen with a bench grinder or sharpening jig

- For carbide: Replace or send out for professional resharpening

- Keep spares: Always have backup bits on hand

Mistake 5: Wrong Bit Type for the Material

The Problem

Using a wood bit on metal, or a masonry bit on wood wastes time, ruins bits, and produces poor results.

The Solution

| Material | Correct Bit Type |

|---|---|

| Wood | Brad point, spade, Forstner, auger |

| Metal | HSS twist bits, cobalt, carbide |

| Concrete/Masonry | Carbide-tipped masonry bits with hammer drill |

| Tile/Glass | Diamond or carbide spear-point bits |

| Plastic | HSS with slow speed, or specialized plastic bits |

Mistake 6: Not Securing the Workpiece

The Problem

Unsecured workpieces can spin, causing injury, damaging the piece, or breaking the bit.

The Solution

- Always clamp: Use vises, C-clamps, or workbench clamps

- Never hand-hold: Small pieces can spin and cause serious cuts

- For sheet metal: Clamp between sacrificial boards

- For round stock: Use V-blocks or pipe clamps

Mistake 7: Ignoring Chip Evacuation

The Problem

Clogged flutes cause overheating, bit jamming, and poor hole quality. Deep holes are especially problematic.

The Solution

- Peck drilling: For deep holes, retract fully every 1-2 bit diameters

- Clear regularly: Pull out and blow/brush chips away

- Watch for signs: Increased resistance, burning smell, chip buildup

- Use compressed air: For blind holes that trap chips

Mistake 8: No Cooling or Lubrication (Metal)

The Problem

Drilling metal without coolant drastically reduces bit life and can damage the workpiece through discoloration and warping.

The Solution

- Steel: Use cutting oil or tapping fluid

- Aluminum: WD-40, kerosene, or specialized aluminum cutting fluid

- Cast iron: Usually drilled dry, but coolant helps for deep holes

- Stainless: Must use coolant—work hardening is severe without it

- Application: Apply before starting and periodically during drilling

Mistake 9: Drilling at an Angle

The Problem

Non-perpendicular drilling causes oval holes, bit walking, and can break bits from side loading.

The Solution

- Use a drill guide: Portable drill guides ensure 90° angles

- Check with a square: Position a speed square next to the bit

- Use a drill press: For precision work, a drill press is ideal

- Visual check: Stand back and sight along the bit before starting

Mistake 10: Not Wearing Safety Gear

The Problem

Metal chips, wood splinters, and concrete dust cause eye injuries. Hot chips can burn skin. Hair and loose clothing can catch in spinning chucks.

The Solution

- Always wear: Safety glasses (not regular glasses)

- For metal: Add face shield for large drilling operations

- For concrete: Use dust mask or respirator

- General: Tie back long hair, remove jewelry, avoid loose sleeves

- Hearing: Use ear protection for prolonged hammer drilling