DIN 338: The Standard (Jobber Length)

The All-Rounder.

If you buy a drill bit set at a shop, 99% of the time it is DIN 338. It offers the perfect balance between reach and rigidity/strength.

Typical Dimensions (10mm Bit):

Total Length: 133mm

Flute Length: 87mm

DIN 340: The Long Series

The Deep Hole Specialist.

DIN 340 bits are extended for drilling deep holes or reaching through thick assemblies. Because they are longer, they are less rigid and more prone to snapping if you wobble the drill.

Typical Dimensions (10mm Bit):

Total Length: 184mm (+51mm longer)

Flute Length: 116mm

DIN 1897: The Stub (Short Series)

The Evaluation Master.

DIN 1897 bits look tiny ("Stubby"). They are designed for:

- Sheet Metal: Short bits don't flex, so they don't "walk" on thin metal.

- CNC Machines: High rigidity for precision production.

- Tight Spaces: Fitting into a drill inside a cramped engine bay.

Typical Dimensions (10mm Bit):

Total Length: 89mm (-44mm shorter)

Flute Length: 43mm

Visual Length Comparison (for 10mm Bit)

| Standard | Common Name | Total Length | Application |

|---|---|---|---|

| DIN 1897 | Stub (Extra Short) | 89 mm | Sheet Metal, CNC |

| DIN 338 | Jobber (Standard) | 133 mm | General Purpose |

| DIN 340 | Long Series | 184 mm | Deep Holes |

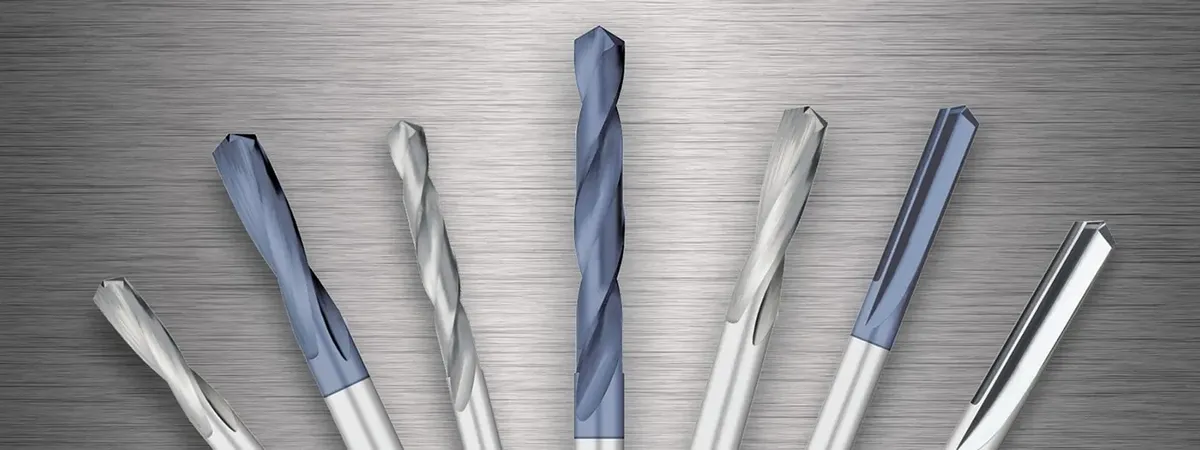

Pro Tip: Material & Geometry

Standard DIN bits are usually HSS with 118° points. For harder materials like Stainless Steel, consider upgrading to Cobalt (HSS-Co) or 135° Split Point bits for better performance.