Why Ordinary Bits Die Instantly

Hardened steel (like Grade 8 bolts, knife blades, or leaf springs) has a high Rockwell hardness. When you try to drill it with a standard HSS black oxide bit, the friction generates massive heat immediately.

Because standard HSS loses its hardness at around 500°C, the cutting edge literally softens and rounds off. You aren't cutting anymore; you are friction welding.

M35 (5%) vs. M42 (8%) Cobalt

The solution is Cobalt. Cobalt increases the "Red Hardness" of the steel, allowing it to stay hard even when glowing hot.

M35 Cobalt (5%)

The Pro's Choice.

- Can drill stainless, cast iron, and medium-hard steel.

- Tough enough to use in a Hand Drill without snapping easily.

- Easier to sharpen than M42.

M42 Cobalt (8%)

The Machinist's Choice.

- Drills the hardest metals (Inconel, Titanium, Hardened Steel).

- More Brittle: Avoid using in a hand drill if possible. Any wobbling effectively snaps the cutting lips.

- Best for Drill Presses.

Technique: Pressure, Speed, and Heat

Drilling hardened steel is not a race. It is a slow, heavy push.

- Center Punch: You MUST use a center punch to keep the bit from walking.

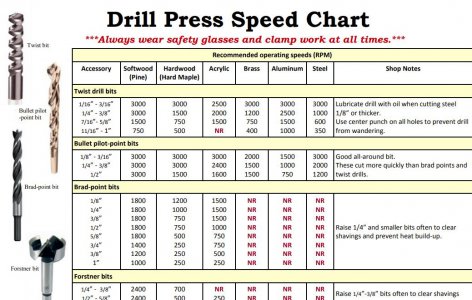

- Slow RPM: Consult our Speeds & Feeds Chart. Think "Low Gear".

- High Pressure: You need to push hard enough so the bit creates continuous chips, not dust. If you see dust, you are rubbing (work hardening).

- Coolant: Keep it wet. Heat is the enemy.

When to Upgrade to Carbide

If "Cobalt" isn't working, the steel might be fully hardened (60+ HRC). In this case, HSS (even M42) will fail.

You need a Solid Carbide or Carbide Tipped drill bit. Use these only in a drill press. They are extremely hard but shatter like glass if you tilt them.