Carbide Grade Overview

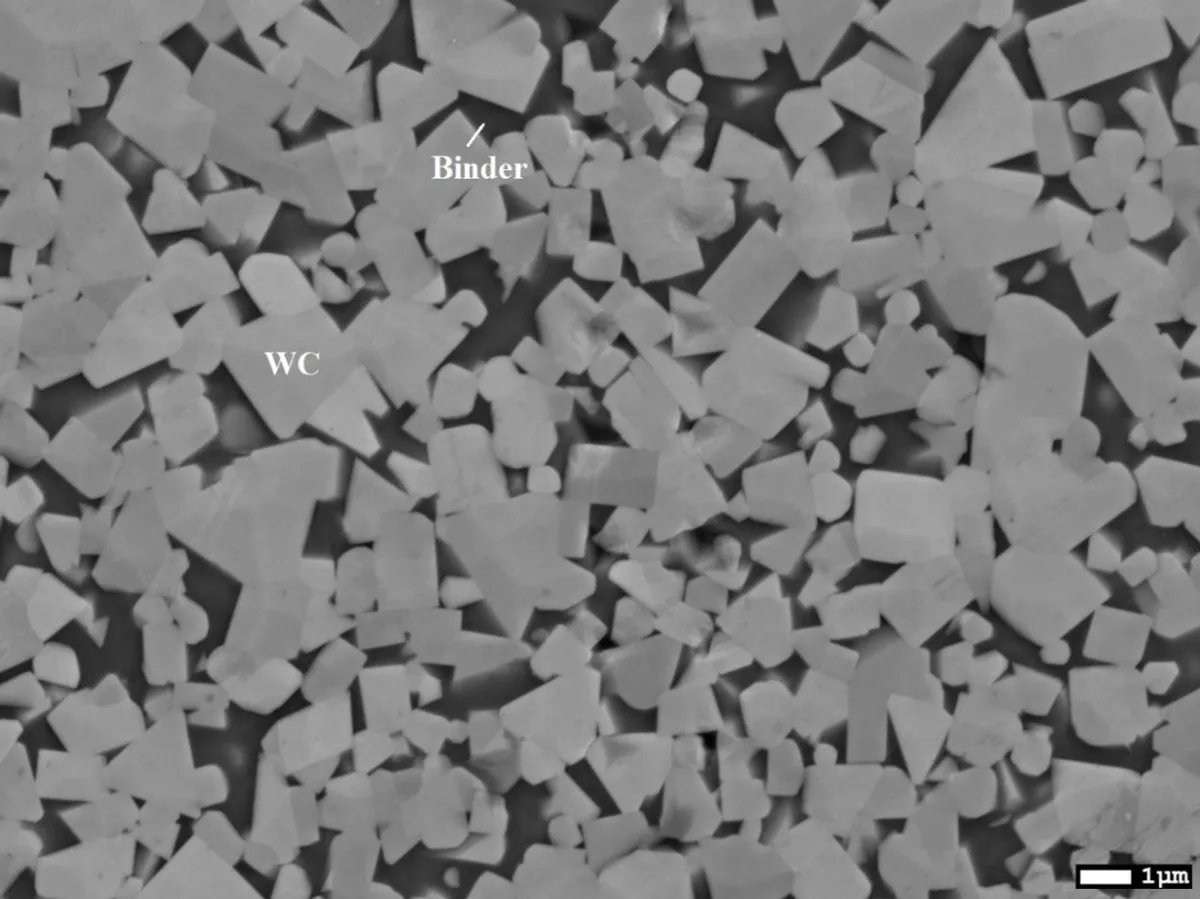

Tungsten carbide (WC-Co) grades are the heart of drill bit performance. The right grade balances hardness for wear resistance with toughness for impact absorption.

Key Parameters

- Cobalt content: Higher = more toughness, lower = more hardness

- Grain size: Fine = harder, Coarse (C) = tougher

- Hardness (HRA): Resistance to wear

- TRS (MPa): Transverse rupture strength - impact resistance

Composition & Properties

YG6 (6% Cobalt)

- Hardness: 91-92 HRA

- TRS: 1500-1700 MPa

- Best for: Soft materials, low-impact drilling

- Wear resistance: Excellent

- Toughness: Low

YG8C (8% Cobalt, Coarse)

- Hardness: 89-90 HRA

- TRS: 2000-2200 MPa

- Best for: General masonry, concrete, brick

- Wear resistance: Good

- Toughness: Medium-High

YG11C (11% Cobalt, Coarse)

- Hardness: 87-88 HRA

- TRS: 2400-2600 MPa

- Best for: Reinforced concrete, heavy impact

- Wear resistance: Moderate

- Toughness: Excellent

Grade Comparison Table

| Property | YG6 | YG8C | YG11C |

|---|---|---|---|

| Cobalt % | 6% | 8% | 11% |

| Hardness (HRA) | 91-92 | 89-90 | 87-88 |

| TRS (MPa) | 1500-1700 | 2000-2200 | 2400-2600 |

| Wear Resistance | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Impact Resistance | ★★☆☆☆ | ★★★★☆ | ★★★★★ |

| Cost | $ | $$ | $$$ |

Application Matching

| Material | Recommended Grade | Reason |

|---|---|---|

| Soft brick, AAC blocks | YG6 | Low impact, high wear |

| Standard concrete | YG8C | Balanced performance |

| Reinforced concrete | YG11C | Rebar impact resistance |

| Granite, hard stone | YG8C | Hardness with toughness |

| Tile, ceramics | YG6 | Precision, low chipping |

Selection Guidelines

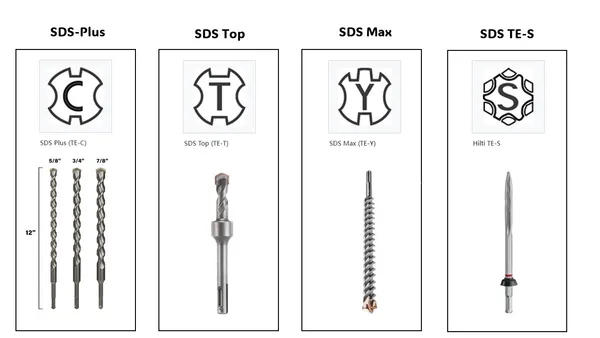

- Identify primary material: What will you drill most often?

- Assess impact level: Rotary-only vs hammer drilling?

- Consider rebar risk: Reinforced concrete needs YG11C

- Balance cost vs life: Higher cobalt = higher cost but longer life in tough conditions

Need carbide grade recommendations for your application? Contact our engineering team.